Basic Info.

Model NO.

01

Available Width

915mm,1250mm, 1500mm, 2000mm

Avaialbe Length

Max 6000mm

Core Materials

Non-Toxic Low Density Polyethylene

Customized

Available

Colors

More Than 100 Colors

Standard

GB/T 17748-2008 Standard

Product Name

Wall Material 3mm Aluminum Composite Panel for Cla

Transport Package

Wood Pallet or in Nude

Specification

1220*2440mm

Trademark

NEITABOND or OEM

Origin

China

HS Code

7606119010

Production Capacity

15000000sqm/Year

Product Description

Wall Material 3mm Aluminum Composite Panel for Cladding

Wall Material 3mm Aluminum Composite Panel for Cladding

| Product name | Wall Material 3mm Aluminum Composite Panel for Cladding |

| Panel size | 1220*24403mm(Standard) 1250*3200mm, 1500*5800mm |

| Panel thickness | 2mm, 3mm, 4mm, 5mm, 6mm |

| Panel width | 915mm, 1000mm,1220mm,1250mm,1500mm,1550mm,2000mm |

| Panel length | 1000mm, 1220mm, 2440mm, 3200mm, 5000mm, 5800mm |

| Skin aluminum thinckness | 1000mm, 1220mm, 2440mm, 3200mm, 5000mm, 5800mm 0.21mm, 0.25mm, 0.3mm, 0.4mm, 0.5mm(outdoors) |

| Coating | PE/PVDF/NANO/PEVE/Nacerous/Brushed/Granite/Mirror surface |

| PE core | Recycle PE Core, Fireproof PE Core, Unbreakable PE Core |

| Aluminum Alloy | AA1100, AA3003 |

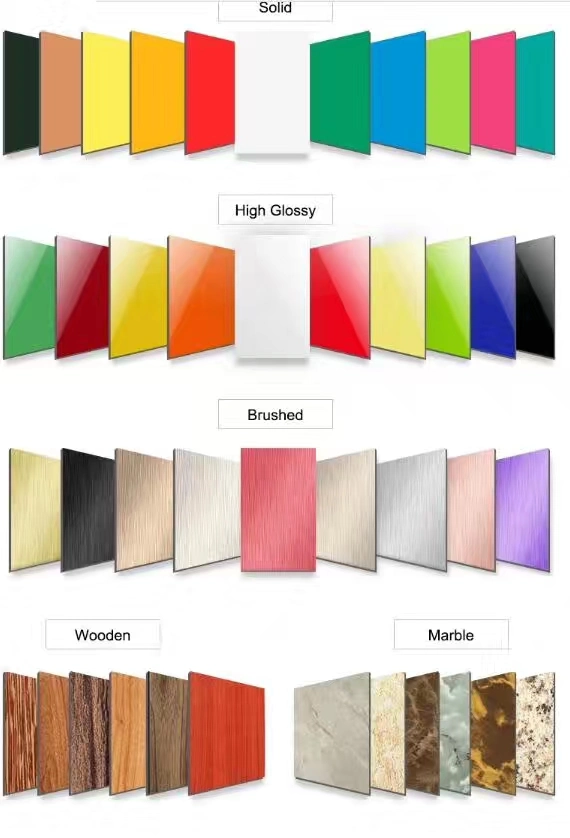

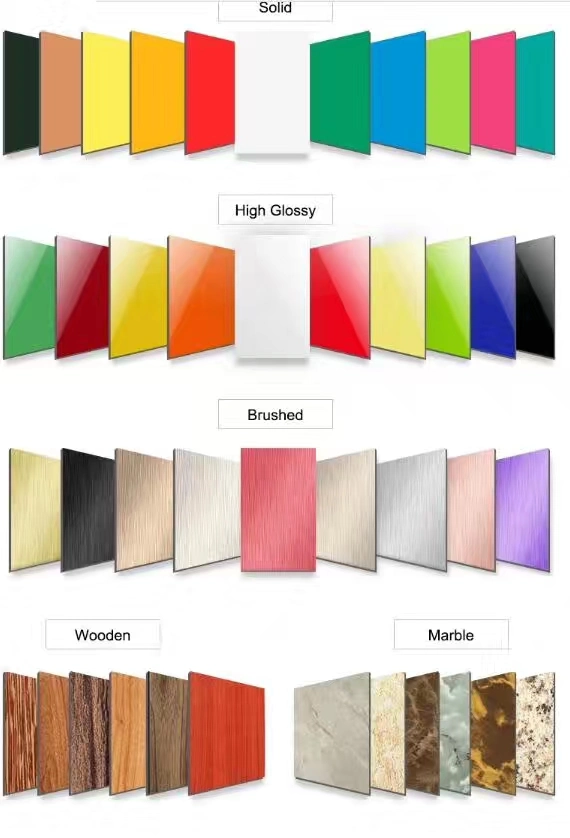

| Color | Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror or as your request |

| Protective Film | Protective film with NEITABOND brand or as your request |

| Certification | ISO9001, SGS, CE, ASTM |

| More service | OEM, Free Samples |

Raw material of aluminum composite panel

More than 90 colors available, PANTONE & RAL accepted

ACP Advantages

ACP Advantages

Front side:aluminum alloy sheet coated with flour-carbon resin(PVDF) or PE painting

Core: nontoxic low density polyethylene.

Back side: aluminum alloy sheet coated with polyethylene resin painting.

Surface finish: treated with PVDF or PE resin rolling roasting coating.

Color Chart More than 90 colors available, PANTONE & RAL accepted

ACP Advantages

ACP Advantages 1/High quality

fire prevention, impact resistance, waterproof, moisture resistance, antibacterial, acid and alkali resistance

corrosion resistance, durable, no dust, easy to clean, comply with national fire protection requirements

corrosion resistance, durable, no dust, easy to clean, comply with national fire protection requirements

2/Simple Structure

easy installation and maintenance, install reasonable, lifespan more than 10-15 years.

3/Safety and Environmental

no need welding, to remove the old project to new project still can be used and no need cutting, just unscrew

the bolts

ACP Apllications

the bolts

ACP Apllications

| Aluminum composite panel Applications | ||||

| 1)Building exterior curtain walls, such as airports, hospitals and research centers | ||||

| 2)Decoration reformation storey-addition for old buildings and movable houses | ||||

| 3)Decoration of interior walls,ceilings,bathrooms,kitchens and balconies | ||||

| 4)Shop's door decoration | ||||

| 5)Advertisement boards,display platforms and signboards, billboards, exhibition desks and notice boards | ||||

| 6)Wallboards and ceilings for tunnel | ||||

| 7)Industrial material , vehicle and boat materials |

Main product

| Aluminum composite panel Series | ||||

| PVDF Series | The surface of PVDF aluminum composite panel is Polyvinylidene Fluoride (pvdf, 70%contents) with good weather resistance, impact resistance, UV resistance, sound and heat resistance, colorful, smooth and beautiful. Its life is about 20 years. It is mainly used for exterior decoration. | |||

| PE Series | PE ACP is a kind of new green composite material which compounded of two layers of aluminum sheets and nontoxic low-density polyethyene (LDPE) by macromolecule adhesive film of American DuPont Company through thermo compression, The coating of the aluminum sheet is polyester coating with UV resistance, Its life is about 15 years. It is mainly used for interior decoration and advertisement board. | |||

| Mirror Series | The surface of the mirror finish ACP is the aluminum sheet that looks like a mirror. The back surface is aluminum sheet with anti-corrosion. The mirror finish ACP has the features of mirror effect, light weight, difficult to break, high strength, can be bent and easy to process. Thanks to those features, mirror finish ACP is increasingly used for interior decoration, especially in ceiling, Cabinet panel, household appliance, furniture. | |||

| Nanometer ACP Series | The coating of surface of nanometer ACP is PVDF coating, and then adds a self-clean layer on the surface of PVDF coating. The self-clean layer can prevent the pollutant such as ash layer and decompose the pollutant in the air to reach self-clean effect. Its features of stain resistance, self-clean, acid resistance, weather resistance of nano is superior to the traditional PVDF ACP. | |||

| Fire-resistant Series | Fire-resistance ACP is a kind of green fire-resistant composite material which is compounded of two layers of aluminum sheet and special low-density polythylene (LDPE) with fire-resistance. The coating of its surface is PE or PVDF coating. The core material is compounded by fire-resistant MGOH, NAOH and PE Polyster, so it has the feature of good fire-resistance which can reach B1 class. | |||

| Drawing Finish Series | Drawing finish ACP is compounded of drawing aluminum sheet, the anti-corrosion aluminum sheet, and nontoxic low-density polyethylene (LDPE). Thanks to the drawing treatment, its appearance is very beautiful. It is widely used for interior decoration,especially in ceiling, Cabinet panel, household appliance, furniture. | |||

Package and shipping

Package and shipping

1/Standard wooden pallet 2/Pack in bulk