Basic Info.

Model NO.

250T

Clamping Force

250t Single Station

Main Cylinder Dia

450mm

Max Opening

600mm

Heating Plate Size

1500*750mm Upper and Lower Plate

Control System

PLC+HMI

Main Motor Power

27.5kw

up Heating Plate Power

40kw

Lower Mold Heating Power

40kw

IR Heating Power

64.4kw*2 up to 400 Degree. C

IR Heating System Transmission

Servo Motor Transmission

Machine Dimension

4500*2280*3450mm

Power Supply

AC 380V 50Hz

Total Power

131.9kw Maxi

Machine Weight

17000kg

Transport Package

Vacum Packing+Wood Box

Specification

1500*750mm

Trademark

Shengsai

Origin

Dongguan, China

HS Code

8477800000

Production Capacity

30 Sets Per Quarter

Product Description

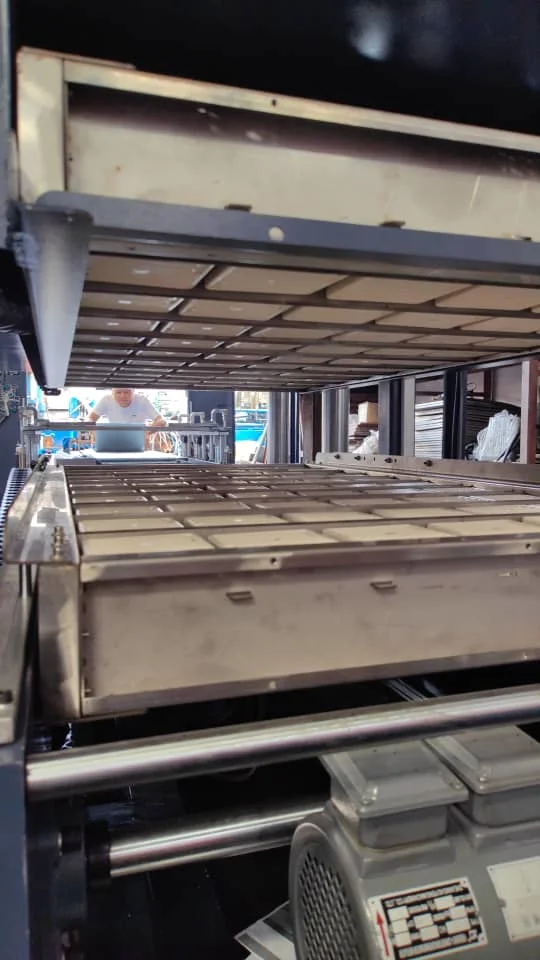

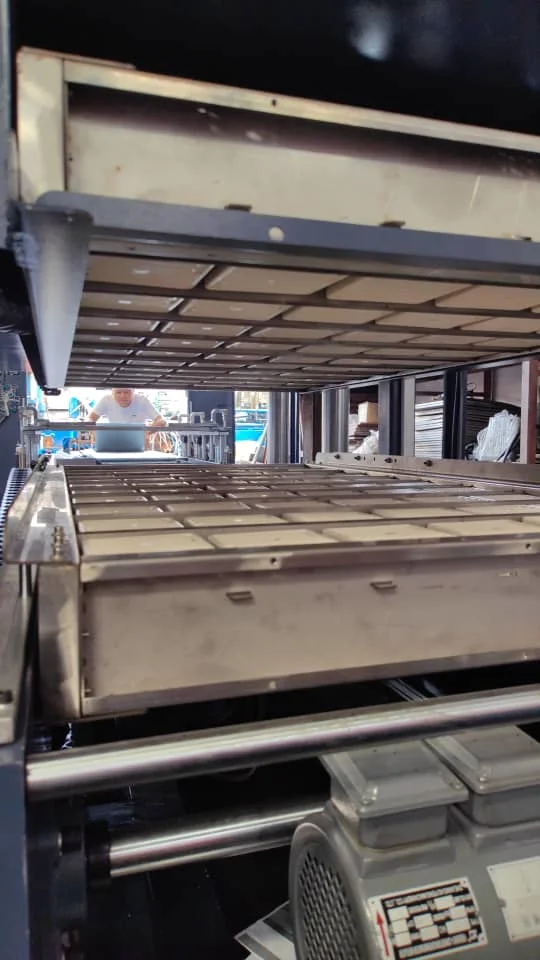

250T High Pressure IMD air forming machine for car interior decoration parts

Application scope of thermoforming equipment:

1, PC+PMMA composite sheet 3D high-pressure four-sided stretching

2, PMMA+PC+PMMA composite sheet 3D high-pressure four-sided stretching

3, ABS+PMMA composite sheet 3D high-pressure four-sided stretching

4, ABS/PC sheet 3D high-pressure four-sided stretching

5. Pressure range: Max 15Mpa (double pressure)

clamping force: 250T

air pressure: 80bar

plate size: 1500*750mm

stroke: 600mm

SERVO motor power: 27.5KW

IR Temp.(MAX): 500ºC

IR heating power: 64.4KW

heating plate power: 40KW

total power: 131.9KW

power supply: 380V 50HZ, 3Phase.

dimension: 450*228*345cm

weight: 17000KG

Molding equipment advantages:

1, clamping force: servo motor control action is stable, accurate, energy saving;

2, air pressure: high compressed air pressure Max: 15Mpa, to meet a variety of complex 3D

Tensile requirements;

3, the main structure: the main force structural parts are cast with ductile iron and good rigidity;

4, high pressure valve: high pressure valve with double section design, accurate pressure control value;

5, monitoring screen: provide molding pressure curve, molding pressure changes at a glance;

6, baking system: infrared heating module using Germany imported Elstein (Erstein) IR

Infrared heater, with temperature control module temperature automatic compensation accurate, IR baking tray moved into /

Moving out adopts servo control, the action is fast and stable;

7. Safety light curtain: the operation window is equipped with safety electric eyes to prevent workers from operating improperly

Accident;

8, mold opening mechanism: designed with automatic lifting fixture, mold opening/closing positioning accurate, reduce

Labor intensity of workers;

9, process storage: the control system provides process storage number, process access and other functions;

10, control system: PLC+ double touch control system

11, safety cover: The whole machine adopts a combined safety cover with transparent window design, the whole

Beautiful and generous.

12, sound and light alarm: with safety eye, program interlock, fault feedback and other functions.

Application scope of thermoforming equipment:

1, PC+PMMA composite sheet 3D high-pressure four-sided stretching

2, PMMA+PC+PMMA composite sheet 3D high-pressure four-sided stretching

3, ABS+PMMA composite sheet 3D high-pressure four-sided stretching

4, ABS/PC sheet 3D high-pressure four-sided stretching

5. Pressure range: Max 15Mpa (double pressure)

clamping force: 250T

air pressure: 80bar

plate size: 1500*750mm

stroke: 600mm

SERVO motor power: 27.5KW

IR Temp.(MAX): 500ºC

IR heating power: 64.4KW

heating plate power: 40KW

total power: 131.9KW

power supply: 380V 50HZ, 3Phase.

dimension: 450*228*345cm

weight: 17000KG

Molding equipment advantages:

1, clamping force: servo motor control action is stable, accurate, energy saving;

2, air pressure: high compressed air pressure Max: 15Mpa, to meet a variety of complex 3D

Tensile requirements;

3, the main structure: the main force structural parts are cast with ductile iron and good rigidity;

4, high pressure valve: high pressure valve with double section design, accurate pressure control value;

5, monitoring screen: provide molding pressure curve, molding pressure changes at a glance;

6, baking system: infrared heating module using Germany imported Elstein (Erstein) IR

Infrared heater, with temperature control module temperature automatic compensation accurate, IR baking tray moved into /

Moving out adopts servo control, the action is fast and stable;

7. Safety light curtain: the operation window is equipped with safety electric eyes to prevent workers from operating improperly

Accident;

8, mold opening mechanism: designed with automatic lifting fixture, mold opening/closing positioning accurate, reduce

Labor intensity of workers;

9, process storage: the control system provides process storage number, process access and other functions;

10, control system: PLC+ double touch control system

11, safety cover: The whole machine adopts a combined safety cover with transparent window design, the whole

Beautiful and generous.

12, sound and light alarm: with safety eye, program interlock, fault feedback and other functions.