Basic Info.

Model NO.

DL-F2200

Certification

CE, ISO9001: 2000, SGS

Customized

Customized

Condition

New

After-sales Service

2 Year

Capacity

50 Rolls /Min

Power

21kw

Usage

Kitchen Towel Making

Automatic

Fully Automatic

Transport Package

Wooden Case

Specification

4800*2350*1850

Trademark

DELE

Origin

China

HS Code

845150000

Production Capacity

10set/Qur

Packaging & Delivery

Package Size

480.00cm * 235.00cm * 175.00cm

Package Gross Weight

2250.000kg

Product Description

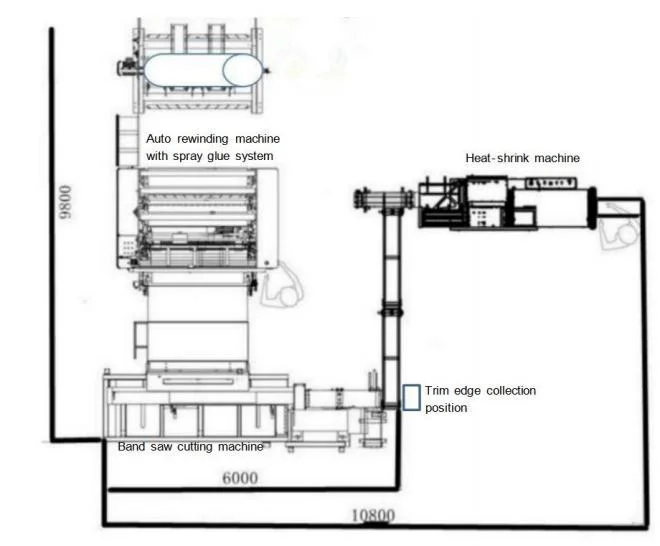

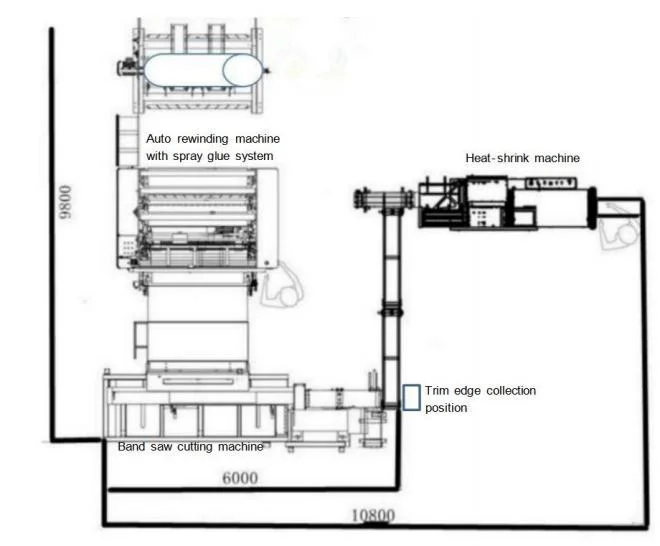

Automatic lazy rag kitchen cloth production line consists of: automatic rewinding machine, big rotary cutter machine, automatic pillow heat shrink packaging machine.

Machine layout:

Fully automatic perforation machine

Fully automatic perforation machine

Raw materials width:2200mm

Raw materials diameter:≤Φ1200mm

Paper core diameter:76mm

Raw materials GSM:35-120 GSM

Feeding system:Single-layer independent rear frame , Dual hair belt, each belt width 200mm, pneumatic control paper delivery belt, (pneumatic paper)

Original paper seat: supporting the customer's original axis (our original paper axis can be selected)

Tension control:Independent drive Independent frequency conversion adjustment for each paper roll

Paper wear mode: Manual guide of paper

Turning mode of guide paper roller: active guide roller in the drive belt part

Cut off disc knife: chain drive cut off (adopt spray device )

Perforation knife:2 pcs

Re-winded rolls diameter:60-240mm

Perforation distance:unlimited

Total power:20kw

Pipe ping mode:automatic

Imported alloy blade for bottom knife

Paper breaking detection: with paper breaking detection system

Pneumatic system: customer-owned system

Speed :120 M/min

Minimum air pressure requirements: 0.45Mpa-0.6Mpa:

Gas consumption: standard status 50 M3 / shift (unit one automatic valve)

Paper delivery belt drive: independent paper rack, installed with independent servo motor on each shaft, Shaft paper roller can be driven independently

Head steel plate thickness: 30 mm thick finishing steel plate

Rear upper paper frame material: 20 mm thick steel plate (with reinforced structure)

Protection: Protective cover for main transmission parts. All transmission parts of the whole machine meet safety protection requirements

Electrical appliances: PLC Delta brand, touch screen Kunlun common state brand frequency converter Inweten brand, servo motor European letter brand.

Automatic log Band Saw Cutting

Machine

Technical parameter:

1 . Cutting speed: 15-30cuts/min

2 . Cutting blade size(L*W*H): 5180*100*1 .05mm

3 . Log length: 2200mm

4 . Cutting diameter: 1 50 - 300mm

5 . Cutting length: max 300mm

6 . Cutting tolerance: ± 2 mm

7 . Power: 15KW ( 380 V 50 Hz 3Phase)

8 . Overall Dimension(L*W*H): 5300*2350*2200mm

9 . Machine weight: 270 0 KG

Heat- shrink machine

Packing big size rolls max diameter 40cm

Technical parameter:

1 . Max packing size L( no limits)* W*H

BF- 850 :W ≤ 650mmH ≤ 300mm (customized) BS- 7550 N:(W )550* H(300) MM

2 . Max sealing size

BF- 850 : Film width ≤ 900mm

BS- 75 5 0 N: tunnel size 1 5 0 0 * 7 5 0 * 5 0 0 mm . 3

Packing speed

BF- 850 : 15-30pcs/min

BS- 755 0 N: 0 - 30m/min

4 . Electric supply and total power

BF- 850 :220v 50hz 2 kw

BS- 7550 N:3 80v 50hz 1 6 kw

5 . Air pressure

BF- 850: 5 kg/cm³

BS- 7550N:/

6 . Weight

BF- 850:450kgs

BS- 7550 N: 320kgs

7 . Dimension (mm)

BF- 850: 2 310 *128 0*1460mm

BS- 7 5 5 0 N:2 10 0 * 8 5 0 * 12 0 0

8 . Label separating machine

9 . Conveyor belt

Machine layout:

Fully automatic perforation machine

Fully automatic perforation machine Raw materials width:2200mm

Raw materials diameter:≤Φ1200mm

Paper core diameter:76mm

Raw materials GSM:35-120 GSM

Feeding system:Single-layer independent rear frame , Dual hair belt, each belt width 200mm, pneumatic control paper delivery belt, (pneumatic paper)

Original paper seat: supporting the customer's original axis (our original paper axis can be selected)

Tension control:Independent drive Independent frequency conversion adjustment for each paper roll

Paper wear mode: Manual guide of paper

Turning mode of guide paper roller: active guide roller in the drive belt part

Cut off disc knife: chain drive cut off (adopt spray device )

Perforation knife:2 pcs

Re-winded rolls diameter:60-240mm

Perforation distance:unlimited

Total power:20kw

Pipe ping mode:automatic

Imported alloy blade for bottom knife

Paper breaking detection: with paper breaking detection system

Pneumatic system: customer-owned system

Speed :120 M/min

Minimum air pressure requirements: 0.45Mpa-0.6Mpa:

Gas consumption: standard status 50 M3 / shift (unit one automatic valve)

Paper delivery belt drive: independent paper rack, installed with independent servo motor on each shaft, Shaft paper roller can be driven independently

Head steel plate thickness: 30 mm thick finishing steel plate

Rear upper paper frame material: 20 mm thick steel plate (with reinforced structure)

Protection: Protective cover for main transmission parts. All transmission parts of the whole machine meet safety protection requirements

Electrical appliances: PLC Delta brand, touch screen Kunlun common state brand frequency converter Inweten brand, servo motor European letter brand.

Automatic log Band Saw Cutting

Machine

Technical parameter:

1 . Cutting speed: 15-30cuts/min

2 . Cutting blade size(L*W*H): 5180*100*1 .05mm

3 . Log length: 2200mm

4 . Cutting diameter: 1 50 - 300mm

5 . Cutting length: max 300mm

6 . Cutting tolerance: ± 2 mm

7 . Power: 15KW ( 380 V 50 Hz 3Phase)

8 . Overall Dimension(L*W*H): 5300*2350*2200mm

9 . Machine weight: 270 0 KG

Heat- shrink machine

Packing big size rolls max diameter 40cm

Technical parameter:

1 . Max packing size L( no limits)* W*H

BF- 850 :W ≤ 650mmH ≤ 300mm (customized) BS- 7550 N:(W )550* H(300) MM

2 . Max sealing size

BF- 850 : Film width ≤ 900mm

BS- 75 5 0 N: tunnel size 1 5 0 0 * 7 5 0 * 5 0 0 mm . 3

Packing speed

BF- 850 : 15-30pcs/min

BS- 755 0 N: 0 - 30m/min

4 . Electric supply and total power

BF- 850 :220v 50hz 2 kw

BS- 7550 N:3 80v 50hz 1 6 kw

5 . Air pressure

BF- 850: 5 kg/cm³

BS- 7550N:/

6 . Weight

BF- 850:450kgs

BS- 7550 N: 320kgs

7 . Dimension (mm)

BF- 850: 2 310 *128 0*1460mm

BS- 7 5 5 0 N:2 10 0 * 8 5 0 * 12 0 0

8 . Label separating machine

9 . Conveyor belt