Basic Info.

Model NO.

HXM368

Structure

Horizontal

Plastic Type

PS,ABS,PP,PE,HDPE,PA,EVA

Plasticizing Way

Screw Type

Clamping Way

Hydraulic & Mechanical

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008

Voltage

380V/50Hz, According to Countries

After Sales Service

Engineers Avaiable to Service Machine

Injection Capacity in Theory

1062 Cm3

Injection Weight

1000 G

Moving Mould-Plate Stroke

710 mm

Space Between Tie Bar

720*690 mm

Transport Package

Standard Package

Specification

6.87*1.89*2.16 M

Trademark

Highsun

Origin

China

HS Code

8477101090

Production Capacity

7000 Sets / Year

Packaging & Delivery

Package Size

687.00cm * 189.00cm * 216.00cm

Package Gross Weight

11000.000kg

Product Description

1.Picture

2. Specifications

3. Advantage

a. SUPER ENERGY SAVING

Output power varies with the load, and no energy is wasted. In the holding pressure phase, the servo motor willreduce speed, with low energy consumption; during the cool-down period, the motor does not work, with zero power consumption. Compared with the ordinary injection molding machines, it can save 20%-80% of the power.

b. HIGH PRECISION AND HIGH STABILITY

Equipped with the precise pressure sensor and rotary encoder, it can respectively monitor and feed back on flow and pressure. Based on the feedback, the high performance synchronous servo motor will adjust flow and pressure accordingly by changing the speed and torque. The closed-loop control can ensure the stability of product quality.

c. HIGH RESPONSE AND HIGH EFFICIENCY

The driving system responses with high sensitivity . It takes only 0.05 seconds to reach maximum value. The response speed is much faster than the ordinary injection molding machines. In that way, it significantly shortens the cycle time and increases the production efficiency.

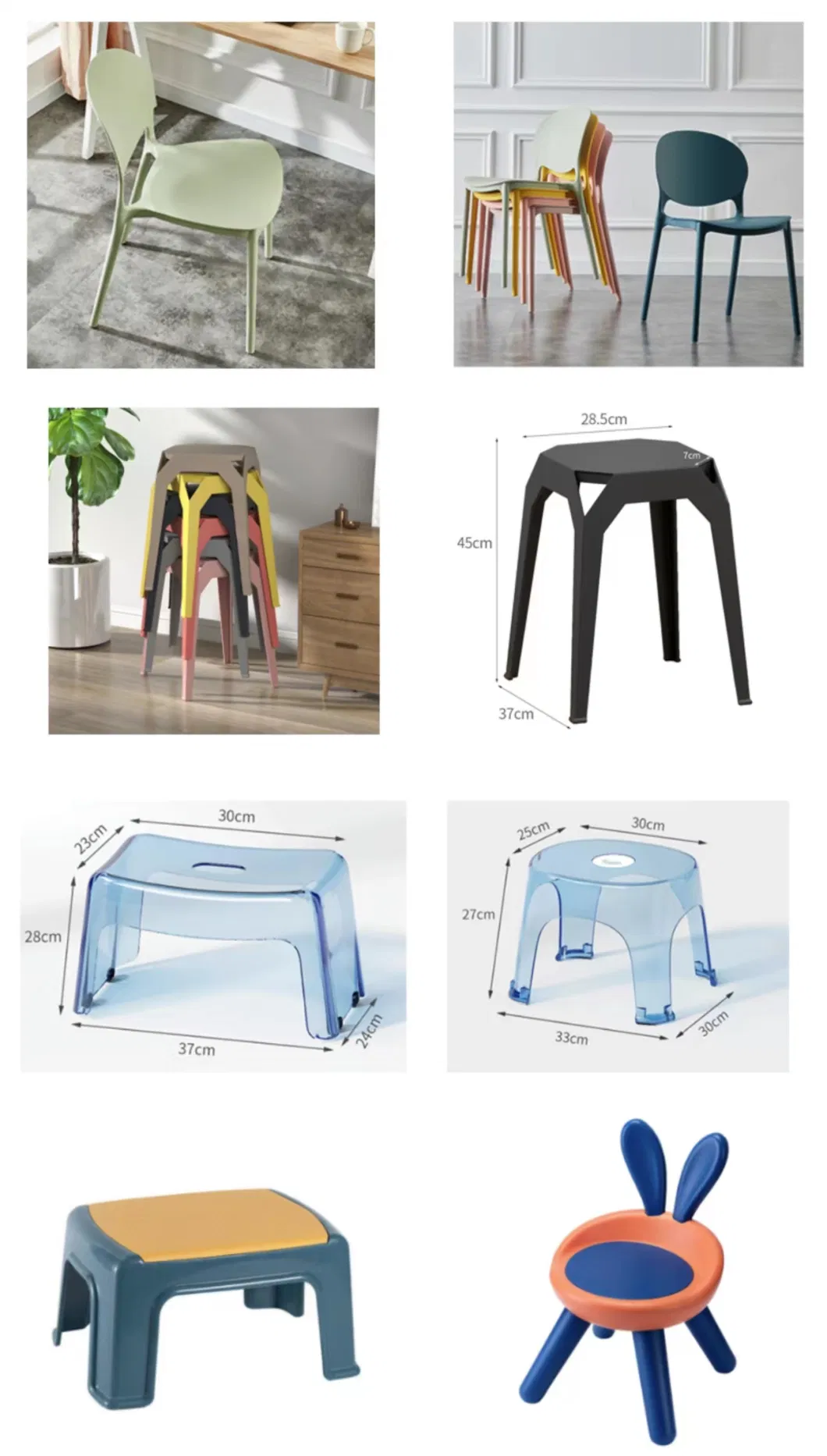

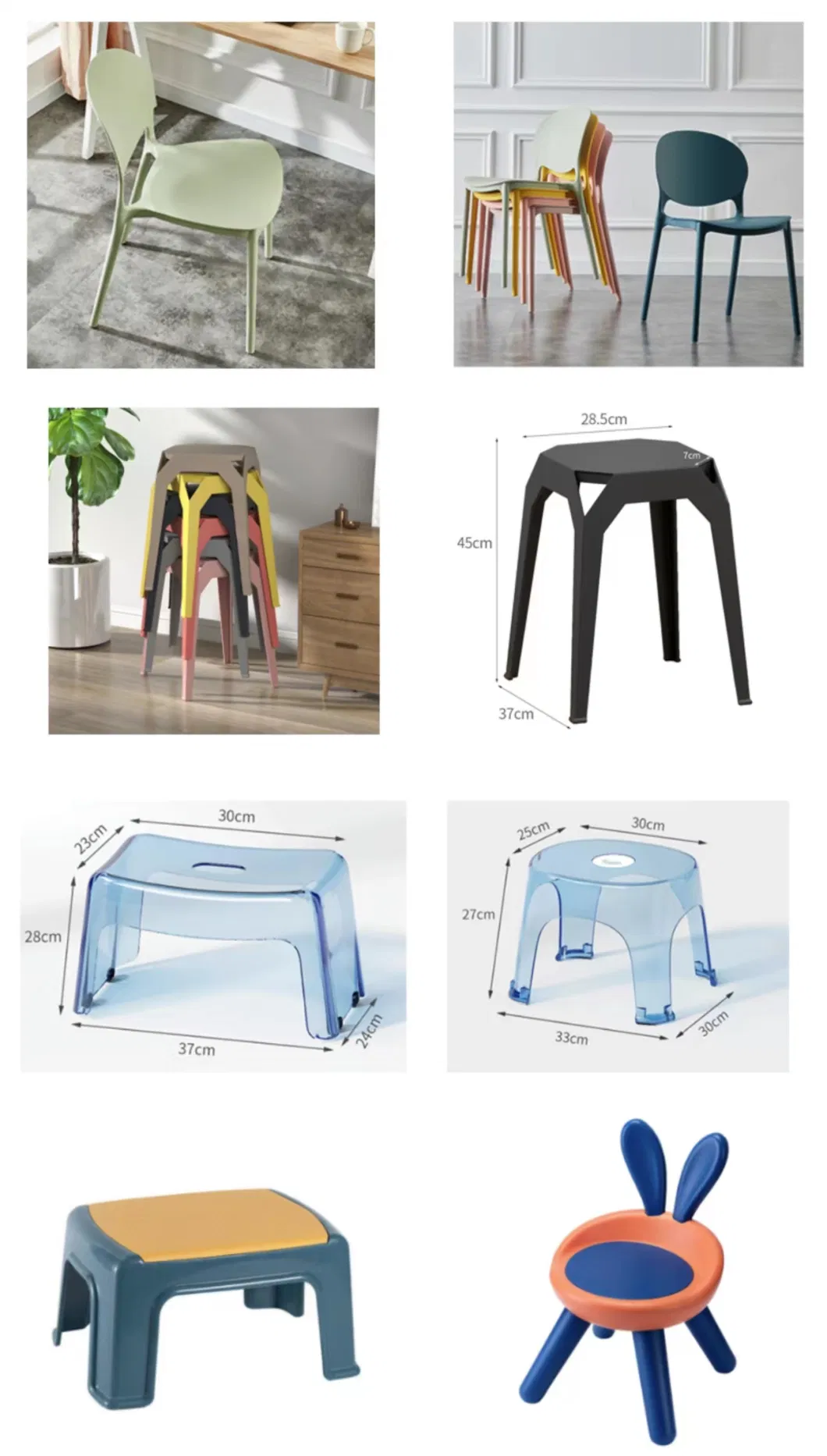

4. Product Produced by Injection Molding Machine

5. Factory

We have six workshops, which are machine development workshop, machine storage workshop, spare parts storage workshop.

We have six workshops, which are machine development workshop, machine storage workshop, spare parts storage workshop.

1 workshop: SP(Middle-speed injection molding machine) and HXYD(Fully-electric and high-speed injection molding machine) production R & D workshop, also stored in the injection molding machine production required parts.

2 workshop: HXM(Servo energy injection molding machine) and HXH(High-speed injection molding machine) production R & D workshop. Storage of manufactured machine, such as HXM 128tons, 158tons, 418tons, 478tons, HXH 260tons, 280tons, 430tons and so on.

3 workshop: HXM(Servo energy injection molding machine), PVC injection molding machine, PET injection molding machine, HXS(Clear two-color injection molding machine) and HXH(High-speed injection molding machine) production R & D workshop. Storage of manufactured machine, such as HXM 98tons, 268tons, from 538tons to 2500tons, HXH 160tons, 200tons, 350tons, 380tons, HXS160tons, 200tons and so on.

4 & 5 workshop: HIGHSUN's independent R & D workshop, automatic processing center. According to customer feedback to the performance of the machine constantly improve, to provide customers with better injection molding machines.

6 workshop: Stored in screw barrel, hopper, hydraulic motor, thermocouple, valve, sheet metal injection molding machine accessories.

6. Company Introduction

China top 1 plastic injecion molding machine

a. Honored with "Top 3" manufacturer of comprehensive strength by NBPMA over the past decade.

b. Established in 1973. Concentrate on Injection Molding field more than 50 years.

c. It covers an area of 1.2 million square feet.

d. Sold to more than 40 countries around the world.

e. Annual output more than 7000sets,ensuring faster delivery time.

f. Worldwide sales reached 130 million US dollars, exports maintain steady growth.

2. Specifications

| MODEL: HXM368-I/i1900 | |||||

| TECHNICAL PARAMETER TABLE | A | B | C | ||

| INJECTION UNIT | SCREW DIAMETER | mm | 60 | 65 | 70 |

| SCREW L/D RATIO | L/D | 22 | 21 | 20 | |

| INJECTION CAPACITY IN THEORY | cm3 | 905 | 1062 | 1232 | |

| INJECTION WEIGHT(PS) | g | 841 | 1000 | 1145 | |

| oz | 29.6 | 34.8 | 40.4 | ||

| INJECTION PRESSURE | MPa | 239 | 204 | 176 | |

| INJECTION RATE | g/s | 229 | 268 | 311 | |

| PLASTICIZING CAPACITY | g/s | 40 | 42 | 47 | |

| SCREW SPEED | rpm | 160 | |||

| CLAMPING UNIT | CLAMPING FORCE | KN | 3680 | ||

| MOVING MOULD-PLATE STROKE | mm | 710 | |||

| MAX. MOULD HEIGHT | mm | 750 | |||

| MIN. MOULD HEIGHT | mm | 250 | |||

| SPACE BWTWEEN TIE-BARS (W*H) | mm | 720*690 | |||

| HYDRAULIC EJECTOR FORCE | KN | 134 | |||

| HYDRAULIC EJECTOR STROKE | mm | 180 | |||

| EJECTOR NUMBER | n | 13 | |||

| OTHERS | PUMP PRESSURE | MPa | 17.5 | ||

| MOTOR POWER | KW | 40 | |||

| HEATING CAPACITY | KW | 20.35 | |||

| MACHINE DIMENSION (L*W*H) | m | 6.87*1.89*2.16 | |||

| MACHINE WEIGHT | t | 11 | |||

| OIL TANK CAPACITY | L | 680 | |||

3. Advantage

a. SUPER ENERGY SAVING

Output power varies with the load, and no energy is wasted. In the holding pressure phase, the servo motor willreduce speed, with low energy consumption; during the cool-down period, the motor does not work, with zero power consumption. Compared with the ordinary injection molding machines, it can save 20%-80% of the power.

b. HIGH PRECISION AND HIGH STABILITY

Equipped with the precise pressure sensor and rotary encoder, it can respectively monitor and feed back on flow and pressure. Based on the feedback, the high performance synchronous servo motor will adjust flow and pressure accordingly by changing the speed and torque. The closed-loop control can ensure the stability of product quality.

c. HIGH RESPONSE AND HIGH EFFICIENCY

The driving system responses with high sensitivity . It takes only 0.05 seconds to reach maximum value. The response speed is much faster than the ordinary injection molding machines. In that way, it significantly shortens the cycle time and increases the production efficiency.

4. Product Produced by Injection Molding Machine

5. Factory

We have six workshops, which are machine development workshop, machine storage workshop, spare parts storage workshop.

We have six workshops, which are machine development workshop, machine storage workshop, spare parts storage workshop.

1 workshop: SP(Middle-speed injection molding machine) and HXYD(Fully-electric and high-speed injection molding machine) production R & D workshop, also stored in the injection molding machine production required parts.

2 workshop: HXM(Servo energy injection molding machine) and HXH(High-speed injection molding machine) production R & D workshop. Storage of manufactured machine, such as HXM 128tons, 158tons, 418tons, 478tons, HXH 260tons, 280tons, 430tons and so on.

3 workshop: HXM(Servo energy injection molding machine), PVC injection molding machine, PET injection molding machine, HXS(Clear two-color injection molding machine) and HXH(High-speed injection molding machine) production R & D workshop. Storage of manufactured machine, such as HXM 98tons, 268tons, from 538tons to 2500tons, HXH 160tons, 200tons, 350tons, 380tons, HXS160tons, 200tons and so on.

4 & 5 workshop: HIGHSUN's independent R & D workshop, automatic processing center. According to customer feedback to the performance of the machine constantly improve, to provide customers with better injection molding machines.

6 workshop: Stored in screw barrel, hopper, hydraulic motor, thermocouple, valve, sheet metal injection molding machine accessories.

6. Company Introduction

China top 1 plastic injecion molding machine

a. Honored with "Top 3" manufacturer of comprehensive strength by NBPMA over the past decade.

b. Established in 1973. Concentrate on Injection Molding field more than 50 years.

c. It covers an area of 1.2 million square feet.

d. Sold to more than 40 countries around the world.

e. Annual output more than 7000sets,ensuring faster delivery time.

f. Worldwide sales reached 130 million US dollars, exports maintain steady growth.