- Overview

- Product Description

- Specification

- Production Process

- Features

- Our Advantages

- Packaging & Shipping

- Application

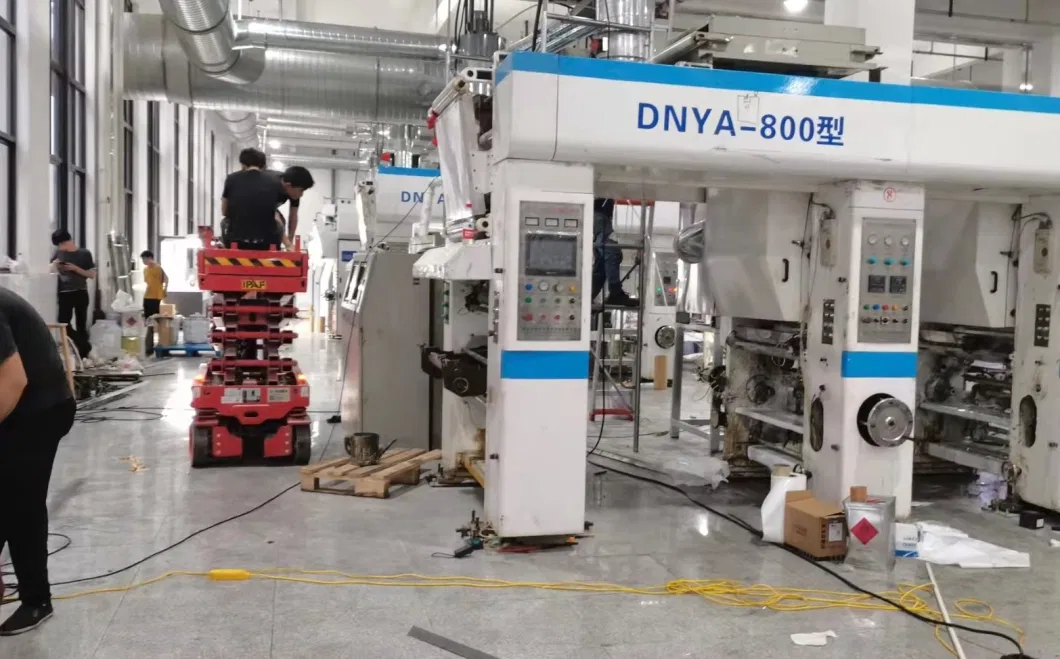

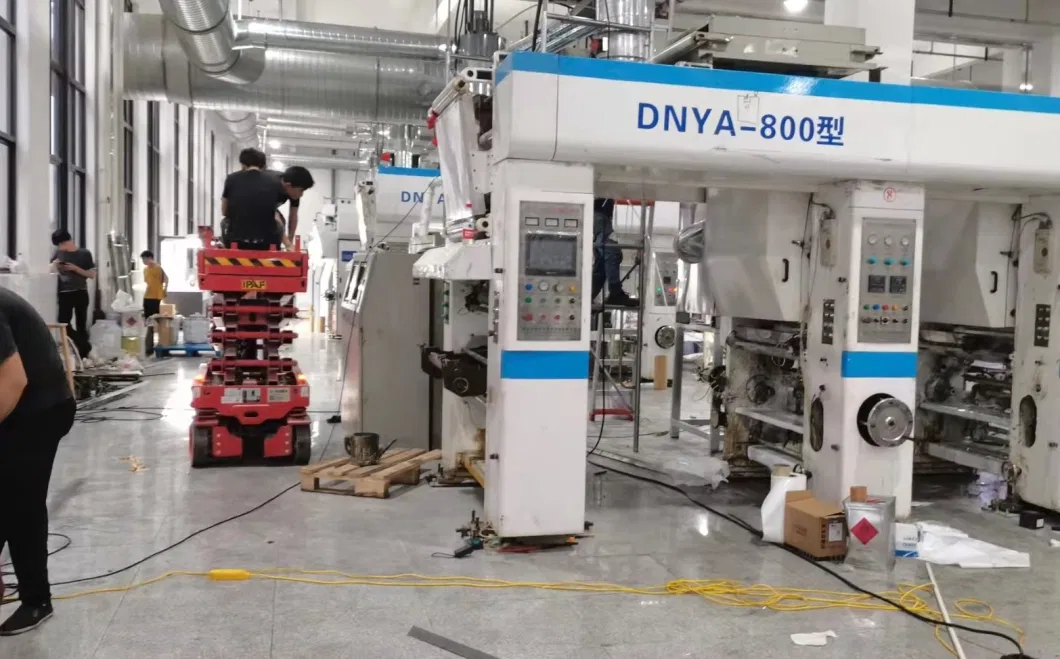

- Company Profile

Basic Info.

Model NO.

IML Label

Color

up to 10 Colors

Thickness

18-110 Microns

Production Time

15 Working Day After Confirm Order

Payment

T/T,Paypal,Credit Card,Western Union,LC etc.

Transport Package

Carton

Specification

Cusomized size

Origin

China

HS Code

4908900000

Production Capacity

10000000square Meters Per Year

Product Description

In-mold label is mainly used for blow molding and injection molding of PP, PE, PET and other materials. Before blowing and injection molding, stick the printed in-mold labels into the blowing and injection mold cavity, the special glue of in-mold labels melts through the action of high temperature and high pressure, then the in-mold labels with the surface of the bottle or injection molding melt into one, when the mold is opened, a beautifully printed bottle or injection is finished a one-time processing.

We offer in-mold labels for injection molding, blow molding and thermoforming. They provide superior graphic reproduction and are 100% recyclable.

Our customers consistently find that in-mold labeling is a cost-effective solution for decorating plastic containers. It removes the need for post-mold labeling, eliminating costly bottlenecks in production and requiring less manufacturing floor space.

In-mold labels work well in either injection mold, blow mold or thermoforming applications, providing the ultimate 'no-label' look even on unique container shapes. These labels provide superior graphic reproduction, with a high degree of product security because of the lack of delamination. In-mold film labels are 100% regrindable and recyclable, which is increasingly important considering today's level of environmental awareness. They also allow for quick design changeovers.

2:low production cost.we can support your reasonable price. help you make more business in your area.

3:100% QC inspection before shipping.

4:Creative designer make design for you by free

5:Over 20 years' manufacturer with ISO certified

6:7-15 days short delivery time

7:Free samples

A new packing forms and different from the traditional direct screen printing, heat shrink labels , stickers. IML is mainly used for PP, PE, PET blow molding and injection molding and other materials on the product.The In Mold Labeling consists in joining the process of thermoforming the product with the process of labeling it in a simultaneous operation. First the label is placed in the mold, where it is maintained in its position by vacuum or electrostatic attraction. Secondly the melted plastic is injected in the mold, where it will become its final shape. Once cold and solid, the label will have become an integral part of the product.

PET film wrap +carton by air PET film wrap + wooden/plastic pallet for sea shipment .

PET film wrap +carton for air ,according customer required

FAQ

1.How can we get a quote ?

We will offer you price referring to your detailed request,so please kindly inform us of the material,size,printing color and other requirements you prefer,and the special offer will be given at once.

2.Can we get some samples?Any Charges?

Yes,you can get available samples in our stock.Free for real samples,but freight cost.

3.How can we know if this product suitable for me?

We can produce various kinds of packing bags&packing films as per your requirements,if you are not sure about the details information,anything about the product you need to know,we can also give some advice for your reference.

If you have other questions, you can contact me.

Packaging &Shipping

Packaging detail: polybag+carton

Delivery detail: in 7~13 days, by sea/by air/by express,up to customer's requirement.

We offer in-mold labels for injection molding, blow molding and thermoforming. They provide superior graphic reproduction and are 100% recyclable.

Our customers consistently find that in-mold labeling is a cost-effective solution for decorating plastic containers. It removes the need for post-mold labeling, eliminating costly bottlenecks in production and requiring less manufacturing floor space.

In-mold labels work well in either injection mold, blow mold or thermoforming applications, providing the ultimate 'no-label' look even on unique container shapes. These labels provide superior graphic reproduction, with a high degree of product security because of the lack of delamination. In-mold film labels are 100% regrindable and recyclable, which is increasingly important considering today's level of environmental awareness. They also allow for quick design changeovers.

| Product name | in mold label | |||

| Size | As per customer's requirement, Max. 1500mm | |||

| Material | Transparent BOPP/OPP | |||

| Surface & performance | Glossy, matte, orange peel etc. metallized silver & gold; scrub, laser, colored light etc. | |||

| Printing | Gravure printing, up to 10 colors | |||

| Thickness | 18-110 micron , as per customer's requirement | |||

| Shape | in roll or pieces, size according to the customer's requests | |||

| Application | PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc | |||

| Packaging | PE bag + carton + packing belt + plastic pallet | |||

| Sample service | Acceptable | |||

| MOQ | 1000square meter (pcs depond on your product size ) | |||

| warranty | 1 year | |||

| production time | cylinder making 5-7 days. label making 5-7 days | |||

| Payment | T/T, Western Union, L/C, Ali accruance pay ;50% deposit and balance before shipment | |||

| shipment | By air/ Express or by Sea, up to clients | |||

| Our Advantages | 1..Free samples are available anytime when you need | |||

| 2.Free design 24 hours online help you | ||||

| 3.we have 13 sets printing machine and can offer you prompt delivery time. | ||||

| 4. import inks ,brighter color and perfect performance | ||||

| 5. we can support you reasonable price. help you make more business in your area | ||||

| How to get your products | ||||

| 1.Artwork | we will make a layout for you,according to your design and size | |||

| 2.Confirm the artwork | You confirm the layout,we will launch your order for plate making | |||

| 3.Plate making(cylinders) | It take about 4-7 days | |||

| 4.Print the film | Print in big rolls - drying - cut into small rolls /piece- quality check. It take about 5-7 days(glitter film needs 5 days more for aluminized) | |||

| 5.Packing | hardboard+ tape+Neutral box + wooden case | |||

| 6.Delivery | By sea/air-up to you | |||

1.Maximum print quality

2.Free and quickly design

3.Environmental protection printing,meet the requierment of international non-toxic standard.

4.Four color process printing design finish in one time,no need for the color register.

5.Simple transfer equipment with vivid printing effect.

6.Strong covering power and good adhesive.

7.High gloss,high image definition,toxic free In the past few years, our company absorbed and digested advanced technologies both at home and abroad.

8.Wide range of look & feel options

1:Import DIC inks, brighter color, and perfect performance,according to the green printing standards, no environmental pollution.4.Four color process printing design finish in one time,no need for the color register.

5.Simple transfer equipment with vivid printing effect.

6.Strong covering power and good adhesive.

7.High gloss,high image definition,toxic free In the past few years, our company absorbed and digested advanced technologies both at home and abroad.

8.Wide range of look & feel options

2:low production cost.we can support your reasonable price. help you make more business in your area.

3:100% QC inspection before shipping.

4:Creative designer make design for you by free

5:Over 20 years' manufacturer with ISO certified

6:7-15 days short delivery time

7:Free samples

A new packing forms and different from the traditional direct screen printing, heat shrink labels , stickers. IML is mainly used for PP, PE, PET blow molding and injection molding and other materials on the product.The In Mold Labeling consists in joining the process of thermoforming the product with the process of labeling it in a simultaneous operation. First the label is placed in the mold, where it is maintained in its position by vacuum or electrostatic attraction. Secondly the melted plastic is injected in the mold, where it will become its final shape. Once cold and solid, the label will have become an integral part of the product.

PET film wrap + wooden/plastic pallet for sea shipment .

PET film wrap +carton by air PET film wrap + wooden/plastic pallet for sea shipment .

PET film wrap +carton for air ,according customer required

1. It may improve efficiency, reduce the cost. Due to the combination of in mould label and plastic product forming happen at the same time ,it does not need to be separately labelled, so it may reduce the cost and energy consumption

2. It may improve the barrier property of products.As in mold label material usually is thin film , so it is waterproof, moistureproof, oilproof, mildewproof, acid and alkali resistant, friction resistant, low temperature resistance and can be soaked.

3,As its beautiful and high-definition printing quality, it is better than the traditional printing process effect.

4. In mold label is embeded into the product, becomes a part of product,so the label will not fall off, looks like no label effect, and has a certain security function.

5.It makes the recyling easier, environmental protection better.Becaue the material of product and in mold label are same or similar, so they can be melted and recycled at the same time, in this way in mold labe reduces the pollution to environment, and meets the standard of green printing.

6. increase the toughness of container mould process, at the same time, save the container resin dosage.

2. It may improve the barrier property of products.As in mold label material usually is thin film , so it is waterproof, moistureproof, oilproof, mildewproof, acid and alkali resistant, friction resistant, low temperature resistance and can be soaked.

3,As its beautiful and high-definition printing quality, it is better than the traditional printing process effect.

4. In mold label is embeded into the product, becomes a part of product,so the label will not fall off, looks like no label effect, and has a certain security function.

5.It makes the recyling easier, environmental protection better.Becaue the material of product and in mold label are same or similar, so they can be melted and recycled at the same time, in this way in mold labe reduces the pollution to environment, and meets the standard of green printing.

6. increase the toughness of container mould process, at the same time, save the container resin dosage.

As it has so many advantages,in mold label is mainly used in below industries:

1. Oil industry , including lubricating oil, gear oil, antifreeze products packaging.

2. Daily chemical product industry, such as shower gel, shampoo, cleaner, detergent and personal care products packaging

3. The food industry: soy sauce, ice cream, coffee, juice, tea drinks, yogurt and other products packaging

4. the pharmaceutical industry: high-grade pharmaceutical packaging

Decai Company is located in No.1 of hongye road Second industry pack ,Wenzhou city. we specialized in all kinds of in-mold labeling, thermal transfer printing and so on. Products can be applied to packages of foods, daily chemical products, agricultural products, plastic product, glasswork, metalwork and timberwork and so on. We are a professional bureaucracy and an intergraded company of research,produce and sales. We has built up a totally new concept of decoration for insiders in the aspect of thermal transfer printing and interior label. Our company enjoyed rich experience, excellent technology, fine quality, low price and cordial service. Its products has been sold all over china, European, America, East Asia and other Asian countries up to now, receiving unanimous praise from users of china and other countries. It affords old and new users perfect service each time with creative design idea, first-rate technicians, strong quality, low price and advanced service idea. Our company holds the core idea of "mutual benefit and cooperative development", enterprise spirit of "continuous innovation,devotion to a bigger and stronger professional company" and development purpose of "quality and integrity comes first".This company is determined to shape itself into a prosperous, influential and renowned enterprise with the aim of uses' satisfaction through technique innovation, inner optimizing management and the improvement of product competition and management level. 2. Daily chemical product industry, such as shower gel, shampoo, cleaner, detergent and personal care products packaging

3. The food industry: soy sauce, ice cream, coffee, juice, tea drinks, yogurt and other products packaging

4. the pharmaceutical industry: high-grade pharmaceutical packaging

FAQ

1.How can we get a quote ?

We will offer you price referring to your detailed request,so please kindly inform us of the material,size,printing color and other requirements you prefer,and the special offer will be given at once.

2.Can we get some samples?Any Charges?

Yes,you can get available samples in our stock.Free for real samples,but freight cost.

3.How can we know if this product suitable for me?

We can produce various kinds of packing bags&packing films as per your requirements,if you are not sure about the details information,anything about the product you need to know,we can also give some advice for your reference.

If you have other questions, you can contact me.

Packaging &Shipping

Packaging detail: polybag+carton

Delivery detail: in 7~13 days, by sea/by air/by express,up to customer's requirement.