Basic Info.

Model NO.

HXH430

Plastic Type

Thermoplastic

Plasticizing Way

Screw Type

Clamping Way

Hydraulic & Mechanical

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008, SGS, TUV

Energy Saving

Servo Energy Saving

After Sales Service

Engineers Avaiable to Service Machine

Voltage

According to Countries

Showroom Locate

Malaysia,Indonesia,Turkey,Mexico,Uzberkista,Mn

Condition

100% New

Machine Weight

17 Ton

Transport Package

Standard Packing

Specification

7.67*1.92*2.16

Trademark

HIGHSUN

Origin

China

HS Code

847710

Production Capacity

7000sets/Year

Packaging & Delivery

Package Size

767.00cm * 192.00cm * 216.00cm

Package Gross Weight

17000.000kg

Product Description

HXH High-speed Series Plastic Injection Moilding Machine

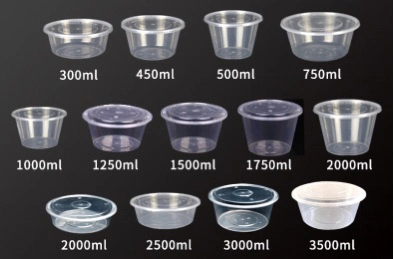

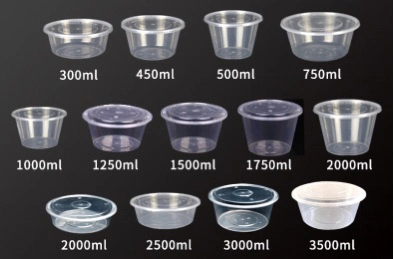

Larger space between tie-bar

The stress distribution of each part of the machine during operation is analyzed by software, the design of the clamping part is optimized according to the high-speed molding requirements for thin-walled products. The HXH series has a larger mold volume compared with the same models from different manufacturers.

Lower energy consumption

All configuration (power system, heating system, cooling system) is optimized according to the requirements of the product molding cycle (fast) and molding characteristics (thin wall). After the test and comparison of clients, it is found that under the same mold and the same output, HXH series can save about 12%-15% energy consumption compared to other brands.

Lighter product weight

The optimized clamping unit ensures the appearance of the product and optimizes the exhaust effect of the mold by using a reasonable clamping pressure. It performs injection molding at a high speed to realize the lightweight of the product

Lower lubricating cost

The unique lubricating and recyclable device realizes the reuse of lubricating oil through the recycling and filtering of lubricating oil, which saves costs for customers. The average annual saving of lubricating oil is about ¥18,000 (lubricating 1 every 300-500 shot)

Enlarged power system

Double motor+Double driver + Double pump

Motion synchronous of opening and charging

Double oil tank&cooling systerm

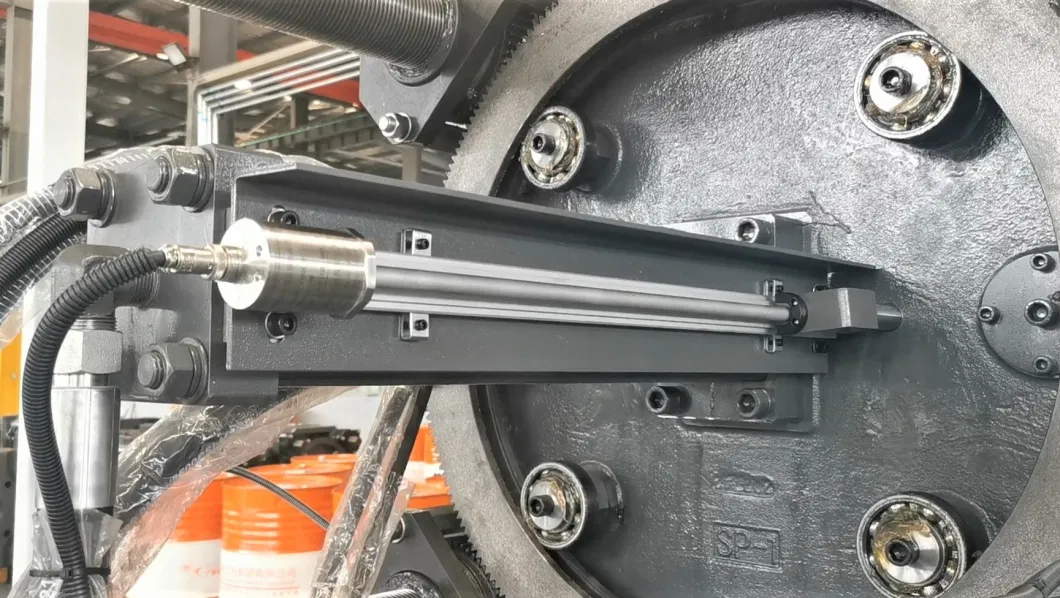

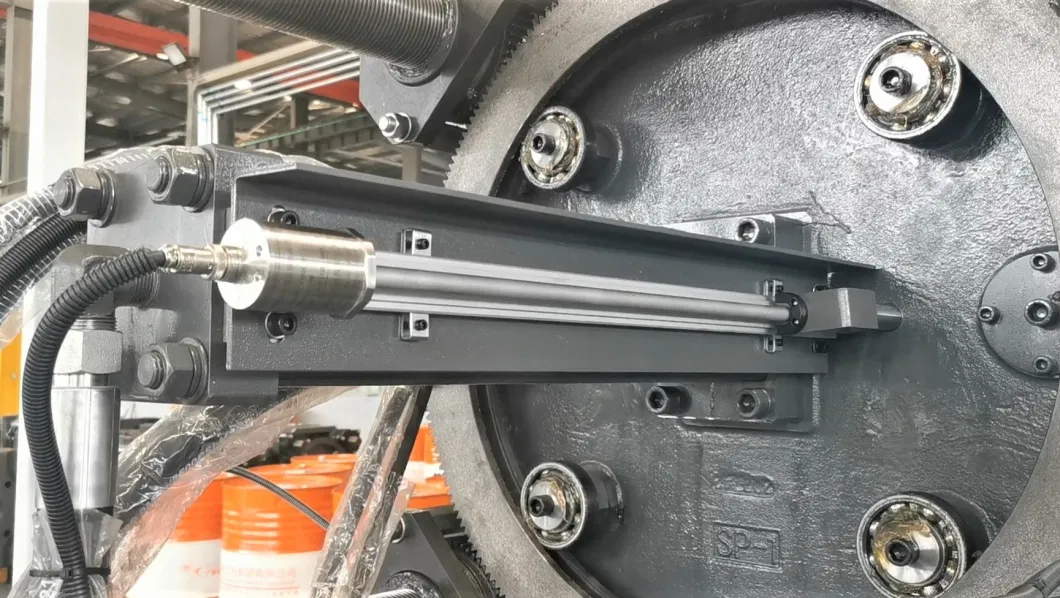

Magnetostrictive displacement sensor

Linear, absolute measurement non-contact measurement;

Highest reliability Rugged industrial displacement sensors non-linear accuracy of ± 0.01%

Larger space between tie-bar

The stress distribution of each part of the machine during operation is analyzed by software, the design of the clamping part is optimized according to the high-speed molding requirements for thin-walled products. The HXH series has a larger mold volume compared with the same models from different manufacturers.

Lower energy consumption

All configuration (power system, heating system, cooling system) is optimized according to the requirements of the product molding cycle (fast) and molding characteristics (thin wall). After the test and comparison of clients, it is found that under the same mold and the same output, HXH series can save about 12%-15% energy consumption compared to other brands.

Lighter product weight

The optimized clamping unit ensures the appearance of the product and optimizes the exhaust effect of the mold by using a reasonable clamping pressure. It performs injection molding at a high speed to realize the lightweight of the product

Lower lubricating cost

The unique lubricating and recyclable device realizes the reuse of lubricating oil through the recycling and filtering of lubricating oil, which saves costs for customers. The average annual saving of lubricating oil is about ¥18,000 (lubricating 1 every 300-500 shot)

| MODEL: HXH430 | ||||

| TECHNICAL PARAMETER TABLE | A | B | ||

| INJECTION UNIT | SCREW DIAMETER | mm | 55 | 60 |

| SCREW L/D RATIO | L/D | 24 | 22 | |

| INJECTION CAPACITY IN THEORY | cm3 | 582 | 692 | |

| INJECTION WEIGHT(PS) | g | 529 | 630 | |

| INJECTION PRESSURE | MPa | 171 | 144 | |

| INJECTION VELOCITY | mm/s | 480 | ||

| PLASTICIZING CAPACITY | g/s | 80 | 97 | |

| SCREW SPEED | rpm | 400 | ||

| CLAMPING UNIT | CLAMPING FORCE | KN | 4300 | |

| MOVING MOULD-PLATE STROKE | mm | 690 | ||

| MAX. MOULD HEIGHT | mm | 780 | ||

| MIN. MOULD HEIGHT | mm | 280 | ||

| SPACE BWTWEEN TIE-BARS (W*H) | mm | 760*710 | ||

| HYDRAULIC EJECTOR FORCE | KN | 181 | ||

| HYDRAULIC EJECTOR STROKE | mm | 180 | ||

| EJECTOR NUMBER | n | 13 | ||

| OTHERS | PUMP PRESSURE | MPa | 19 | |

| MOTOR/DRIVING POWER | KW | 45+45 | ||

| HEATING CAPACITY | KW | 20.3 | ||

| MACHINE DIMENSION (L*W*H) | m | 7.67*1.92*2.16 | ||

| MACHINE WEIGHT | t | 17 | ||

| OIL TANK CAPACITY | L | 850 | ||

Optimized design of complete mould platen and toggle structure with best stress analysis

Adopt cast iron QT550-2 of cast iron,

Hardness: 245-295 BH

(Brinell Hardness: normally is 160-210 of QT450-10)

Bigger foot-pad improving with stability of foundation

Using graphite steel of bushes improve bearing resistance and abrasive resistance

Adopt cast iron QT550-2 of cast iron,

Hardness: 245-295 BH

(Brinell Hardness: normally is 160-210 of QT450-10)

Bigger foot-pad improving with stability of foundation

Using graphite steel of bushes improve bearing resistance and abrasive resistance

NM infrared heating system

Super energy saving :

70% saving compare ordinary heating band;

Higher-efficiency heating: 15 mins;

Better temperature holding

Super energy saving :

70% saving compare ordinary heating band;

Higher-efficiency heating: 15 mins;

Better temperature holding

Single-cylinder injection platform structure,

small movement inertia,

short acceleration time and high injection repeat accuracy.

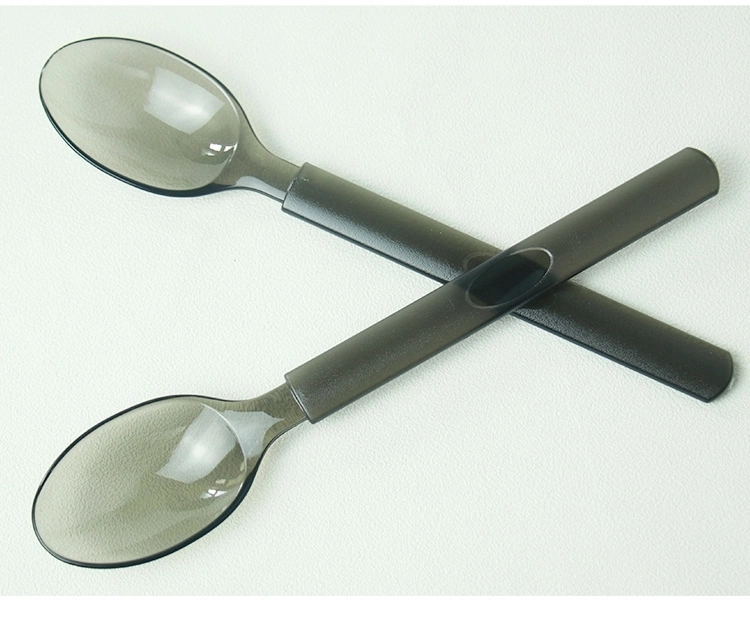

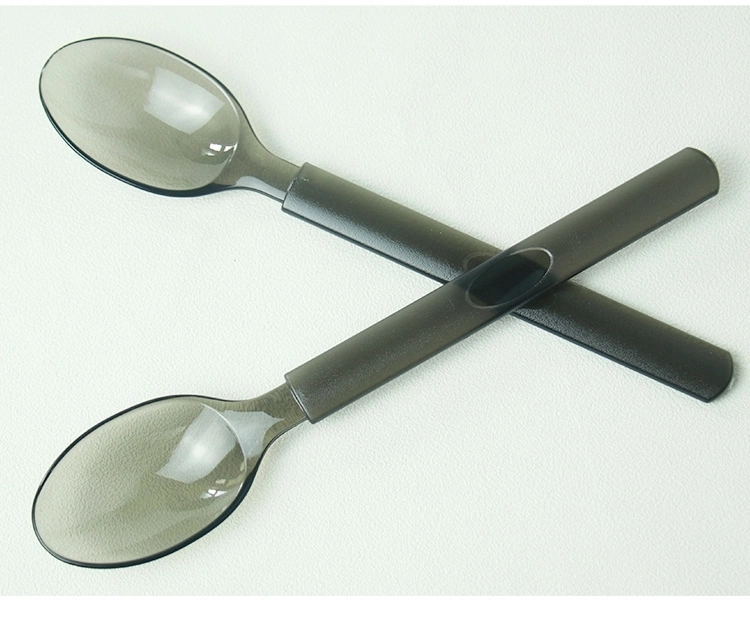

A variety of injection unit options to meet more product production needs

small movement inertia,

short acceleration time and high injection repeat accuracy.

A variety of injection unit options to meet more product production needs

Enlarged power system

Double motor+Double driver + Double pump

Motion synchronous of opening and charging

Double oil tank&cooling systerm

Magnetostrictive displacement sensor

Linear, absolute measurement non-contact measurement;

Highest reliability Rugged industrial displacement sensors non-linear accuracy of ± 0.01%

|

|

|