Basic Info.

Model NO.

HW-645

Plastic Material

ABS

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Cold Runner

Design Software

Pro-E

Installation

Fixed

Certification

ISO

Standard

DME

Customized

Customized

Mold Material

M2,Skh-9,Skh-51,M35,M42,Sp23, P20, 718, 718h,

Enginnering Plastic

PC, ABS,PA, PA6, PA66, PC+ABS, PA46, PA+30% GF

Mold of Steel Suppliers

Finkl,Assab,Daido,Lkm,Buderus

Surface Treatment

Heat Treatment, Polishing, Plating, Machining

Mold Base

Lkm 50 Standard Mould Base or Self-Made

Ejection System

Stripper Plate,Lifter,Push Bar,Ejection Pin etc

Mould Life

>300 Thousand Times

Shipping Packing

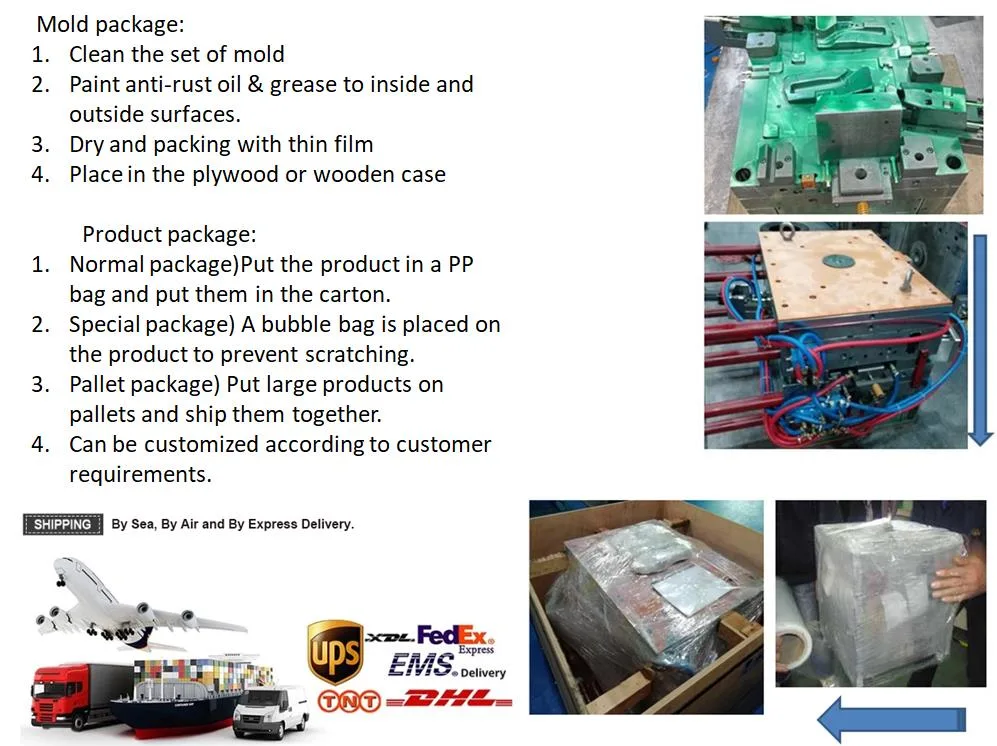

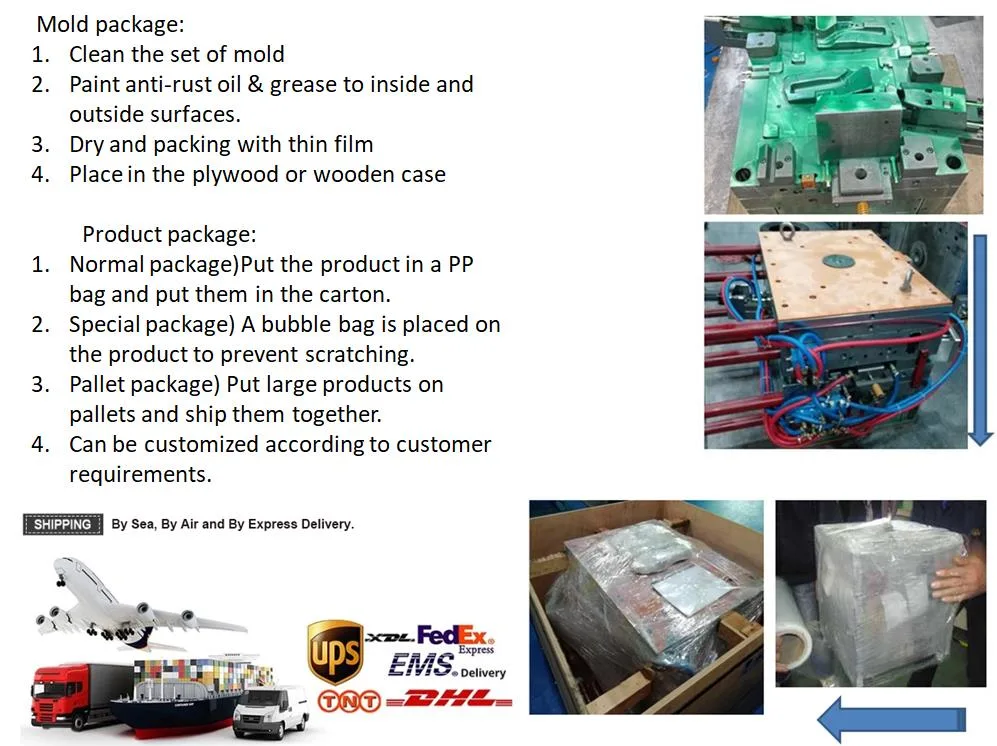

Wood Case or Carton Box

Lead Timelead Time of First Samples

Around 4~7weeks

Export Country

Janpan,Europe,USA,Mexico,Australia,Middle East,Kor

Transport Package

Wood Box and Wood Pallet

Specification

According to your drawing

Trademark

Custom

Origin

Guangdong, China

HS Code

8480719090

Production Capacity

40sets/Month

Packaging & Delivery

Package Size

45.00cm * 66.00cm * 42.00cm

Package Gross Weight

720.000kg

Product Description

custom different type acrylic mould high glossy finish with plastic mould

Our products include :

1.Custom Plastic Injection Parts

2.Multi-cavity plastic parts

3.High Precision Molds

4.Insert & over molding

5.Double Shot Mold(2K mold)

6.Unscrewing Molding

7.Gas-assisted Molding

8.Die Casting Molding

9.Prototype plastic parts and Low cycle plastic parts molding

10Gas Assist molding

11.Elastomeric molding

12.IML & IMD part production

13.Thin wall plastic molding

14.High temperature molding

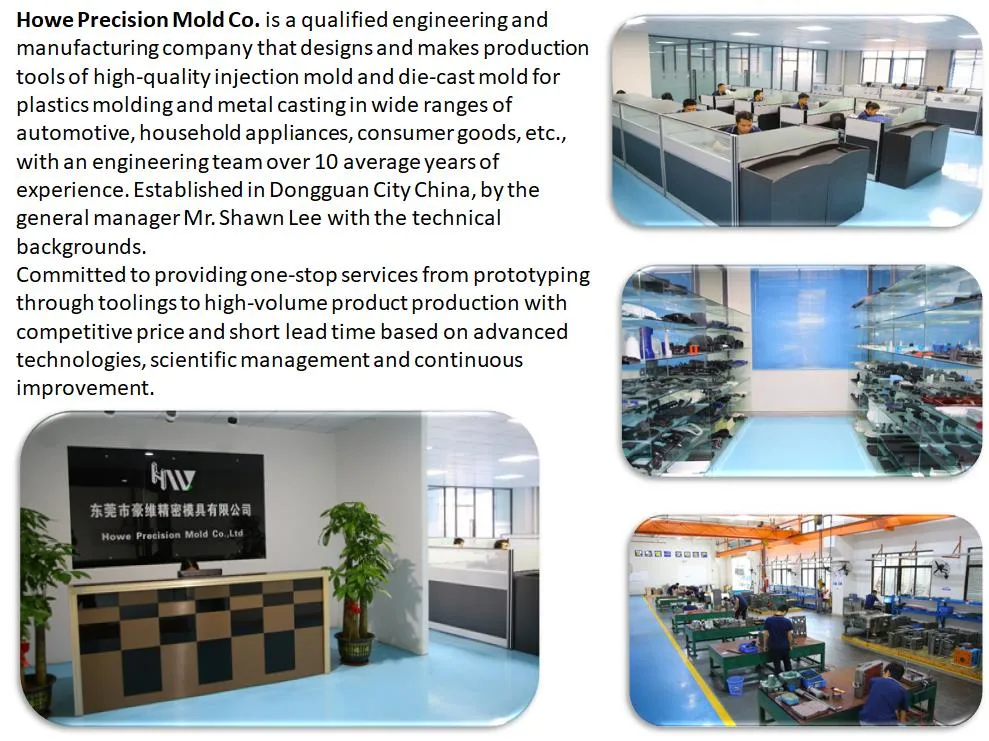

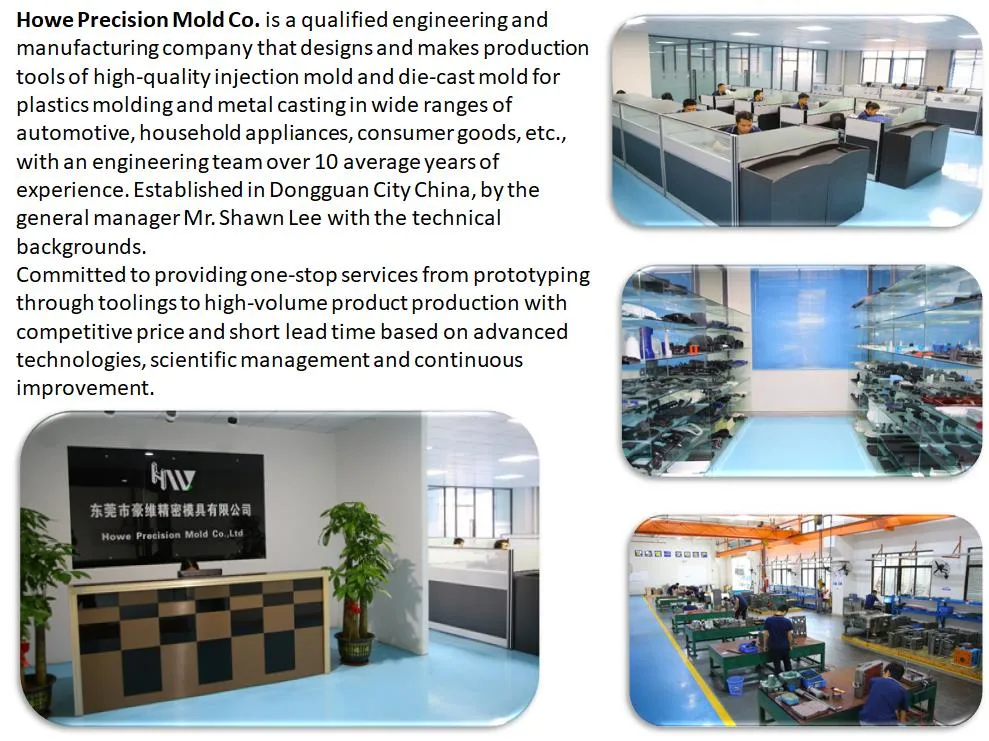

Company Profile

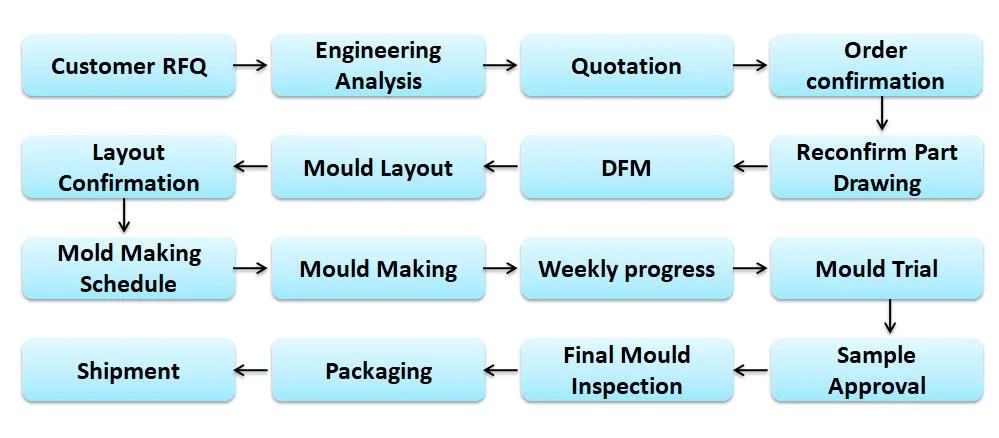

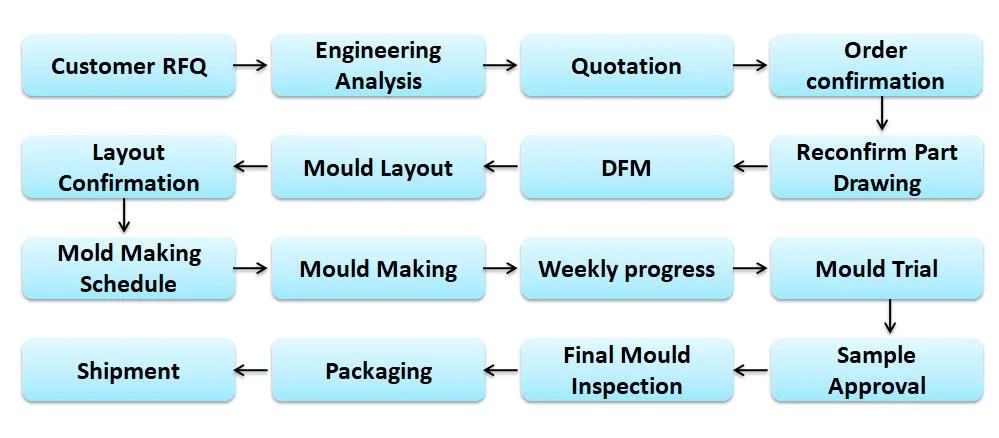

How to order from HOWE?

1. Inquiry-Professional quotation.

2. Confirm the price. lead time. artwork. payment term etc.

3. Howe sales send the Proforma Invoice with Howe company seal.

4. Customer make the payment for deposit and send us Bank receipt.

5.Initial Production Stage-Inform the clients that we have got the payment and will make the samples according to your request, send you photos or Samples to get your approval. After approval, we inform that we will arrange the production & inform the estimated time.

6. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again.

7. End Production-Mass production products photos and samples will send to you for approval. You can also arrange the third party Inspection .

8. Client make payment for balance and Howe ship the cargo. Also Howe can accept payment term-Balance against TT,Paypal or D/P payment Term.

9. Order can be say "finish" when you receive the goods and satisfy with them .

10. Feedback to Howe about Quality. Service. Market Feedback & Suggestion. And we can do better .

Our Team

Our services

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination is incorporated into the actual product! If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!Our products include :

1. Custom Plastic Injection Parts

2. Multi-cavity plastic parts

3. High Precision Molds

4. Insert & over molding

5. Double Shot Mold(2K mold)

6. Unscrewing Molding

7. Gas-assisted Molding

8. Die Casting Molding

9. Prototype plastic parts and Low cycle plastic parts molding

10. Gas Assist molding

11. Elastomeric molding

12. IML & IMD part production

13. Thin wall plastic molding

14. High temperature molding

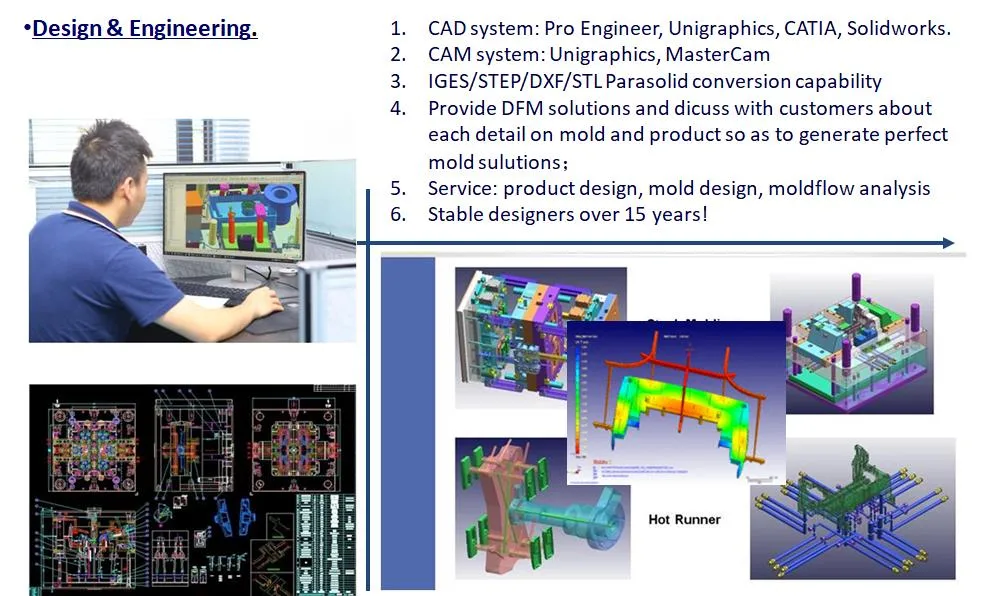

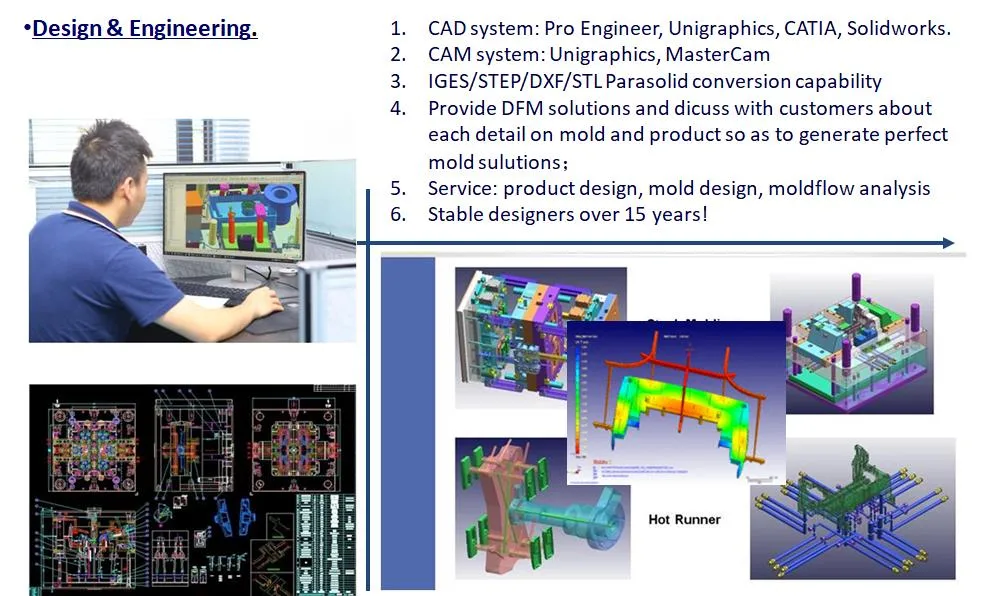

Manufacturing Capability

Quality Control

Work Shop

Customers Visiting

Why choose us?

1. Manufacturing and exporting experience for nearly 10 years. ISO 9001 approved

2. Products are supplied to over 20 countries.

3. One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. 24 hours (two shifts) / 6 days for production.

8. Professional design team, mold maker engineer. OEM/ODM service.

9. Professional QC and R&D teams to assure high quality.

10. Professional sales team. Good English capabilities and communication skills.

11. No MOQ.

12. Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

13. Geographical advantages: within 30 minutes to airport or sea port, near to Hongkong.

You can know more about us from howemold.en.made-in-china.com, Looking forward to having a good start for our reliable cooperation!

Package

F A Q

* Are you factory or trading company?

HOWE is a plastic mold factory in Dongguan, China, welcome to visit us.

* Is HOWE an ISO registered company?

Yes, GBM is an ISO 9001:2015 certified mold manufacturer, we take pride in our constantly improving process and always try to add

value for customers with the best efforts.

* What type of tooling services do you offer?

HOWE can help you manufacture, assemble and printing for your plastic parts. Besides normal molding process, HOWE has deep expertise of 2-shots molding, over-moulding and vertical insert molding.

* Do you have in-house mold design?

Yes, we have our own design team, our engineering manager has over 10 years' experience.

* How long it takes to design my mold?

The mold design timeline is dependent upon the complexity of the project. A simple construction mold can be designed in 1 or 2 days, while a complex mold can take several weeks. HOWE designers and project manager will work closely with you to design your mold in prefessional and efficient manner.

Our products include :

1.Custom Plastic Injection Parts

2.Multi-cavity plastic parts

3.High Precision Molds

4.Insert & over molding

5.Double Shot Mold(2K mold)

6.Unscrewing Molding

7.Gas-assisted Molding

8.Die Casting Molding

9.Prototype plastic parts and Low cycle plastic parts molding

10Gas Assist molding

11.Elastomeric molding

12.IML & IMD part production

13.Thin wall plastic molding

14.High temperature molding

| PLASTIC INJECTION PART BASIC INFORMATION | |

| Product Name | High Precision Mould |

| Product Material | ABS, PA, PA66+30GF, PBT, PC, POM, PP, PE, MA,PVC,TPE,TPU etc |

| Surface Requirement | Smooth, Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser Etching, Anodizing,Brushing |

| Plastic Part Resin | thermoplastic/Thermosetting |

| Tolerance Request | UP to (±0.005mm) |

| Lifetime | >300 Thousand Times |

| Part Size Range | 5-1000mm,or customized |

| Multi Injection | Single/Double/multi color |

| Design Software | Pro/E,UG,Catia,Woodwork,Moldflow,AutoCad |

| Quality Assurance | Design Control, Steel Hardness Inspection Report, Steel Dimension Control Report, Mold Core and Cavity Dimension Inspection Report |

| PLASTIC INJECTION MOULD BASIC DESCRIPTION | |

| Injection System | Hot /Cold Runner |

| Inserts(cavity and core) | H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or as your request |

| Mold Cavity | 1*1,1+1,1*2,1+1+1,etc |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Ejector System | Stripper plate,Lifter,Push bar,Ejection pin etc |

| Steel for Mould | P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc. |

| Steel Standard | FINKL,Assab,DAIDO,LKM,Buderus |

| Cooling | Baffles/Sprin Piple/3D printing water line |

| Lead time of first samples | Around 4~7weeks |

| Standard Parts/Cylinders | DME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/Merkle |

| Design Capability | DFM,Mould flow analysis,Product optimization, Full 2D & 3D mould design,Reverse engineering,Collaborative design with customer's idea |

| Documents / Reports Provided | Fully drawing,Weekly Processing Report, Steel Dimension report, Processing Report,Sample Dimension Report. |

Company Profile

How to order from HOWE?

1. Inquiry-Professional quotation.

2. Confirm the price. lead time. artwork. payment term etc.

3. Howe sales send the Proforma Invoice with Howe company seal.

4. Customer make the payment for deposit and send us Bank receipt.

5.Initial Production Stage-Inform the clients that we have got the payment and will make the samples according to your request, send you photos or Samples to get your approval. After approval, we inform that we will arrange the production & inform the estimated time.

6. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again.

7. End Production-Mass production products photos and samples will send to you for approval. You can also arrange the third party Inspection .

8. Client make payment for balance and Howe ship the cargo. Also Howe can accept payment term-Balance against TT,Paypal or D/P payment Term.

9. Order can be say "finish" when you receive the goods and satisfy with them .

10. Feedback to Howe about Quality. Service. Market Feedback & Suggestion. And we can do better .

Our Team

Our services

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination is incorporated into the actual product! If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!Our products include :

1. Custom Plastic Injection Parts

2. Multi-cavity plastic parts

3. High Precision Molds

4. Insert & over molding

5. Double Shot Mold(2K mold)

6. Unscrewing Molding

7. Gas-assisted Molding

8. Die Casting Molding

9. Prototype plastic parts and Low cycle plastic parts molding

10. Gas Assist molding

11. Elastomeric molding

12. IML & IMD part production

13. Thin wall plastic molding

14. High temperature molding

Manufacturing Capability

Quality Control

Work Shop

Customers Visiting

Why choose us?

1. Manufacturing and exporting experience for nearly 10 years. ISO 9001 approved

2. Products are supplied to over 20 countries.

3. One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. 24 hours (two shifts) / 6 days for production.

8. Professional design team, mold maker engineer. OEM/ODM service.

9. Professional QC and R&D teams to assure high quality.

10. Professional sales team. Good English capabilities and communication skills.

11. No MOQ.

12. Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

13. Geographical advantages: within 30 minutes to airport or sea port, near to Hongkong.

You can know more about us from howemold.en.made-in-china.com, Looking forward to having a good start for our reliable cooperation!

Package

F A Q

* Are you factory or trading company?

HOWE is a plastic mold factory in Dongguan, China, welcome to visit us.

* Is HOWE an ISO registered company?

Yes, GBM is an ISO 9001:2015 certified mold manufacturer, we take pride in our constantly improving process and always try to add

value for customers with the best efforts.

* What type of tooling services do you offer?

HOWE can help you manufacture, assemble and printing for your plastic parts. Besides normal molding process, HOWE has deep expertise of 2-shots molding, over-moulding and vertical insert molding.

* Do you have in-house mold design?

Yes, we have our own design team, our engineering manager has over 10 years' experience.

* How long it takes to design my mold?

The mold design timeline is dependent upon the complexity of the project. A simple construction mold can be designed in 1 or 2 days, while a complex mold can take several weeks. HOWE designers and project manager will work closely with you to design your mold in prefessional and efficient manner.