Basic Info.

Model NO.

HW-201009-1

Plastic Material

ABS

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Hot Runner

Design Software

Ug, Autocad

Installation

Semi Fixed

Certification

CE, ISO

Standard

HASCO

Customized

Customized

Core and Cavity Material

DIN2312, 2738, 2344, 718h, S136h, 8407, Nak80, SKD

Hardness of Steel

46~56HRC

Mold Gate

Fan Gate, Sub Gate, Pinpoint Gate, Valve

Ejection System

Stripper Plate, Lifter, Push Bar, Ejection Pin, Et

Mold Life

500,000 Shots - 2,000,000 Shots

Steel Treatment

Heat Treatment, Nitriding, Chrome Plating

Transport Package

PE Film for Plastic Parts, Wooden Case for Moulds

Specification

According to customers′ drawings

Trademark

HOWE/OEM

Origin

Dongguan, China

HS Code

8480719090

Production Capacity

50sets/Month

Packaging & Delivery

Package Size

62.00cm * 60.00cm * 80.00cm

Package Gross Weight

853.000kg

Product Description

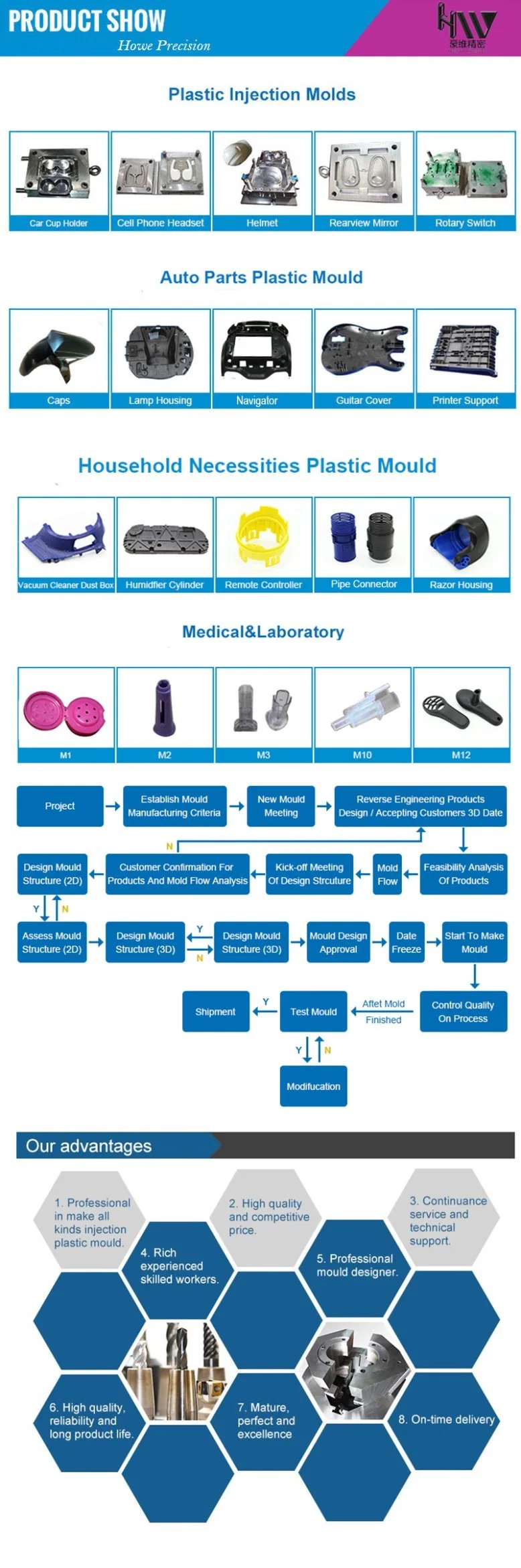

3D VR glasses digital parts plastic toolings injection mould

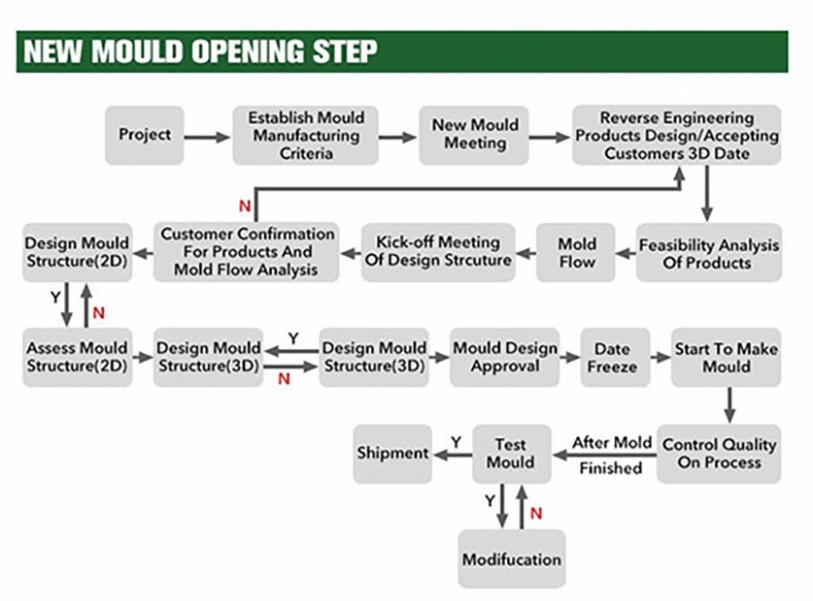

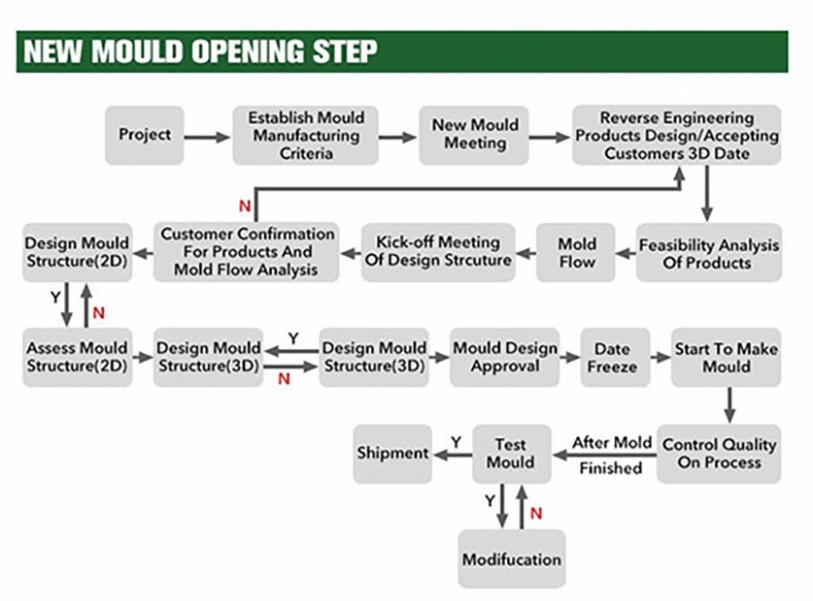

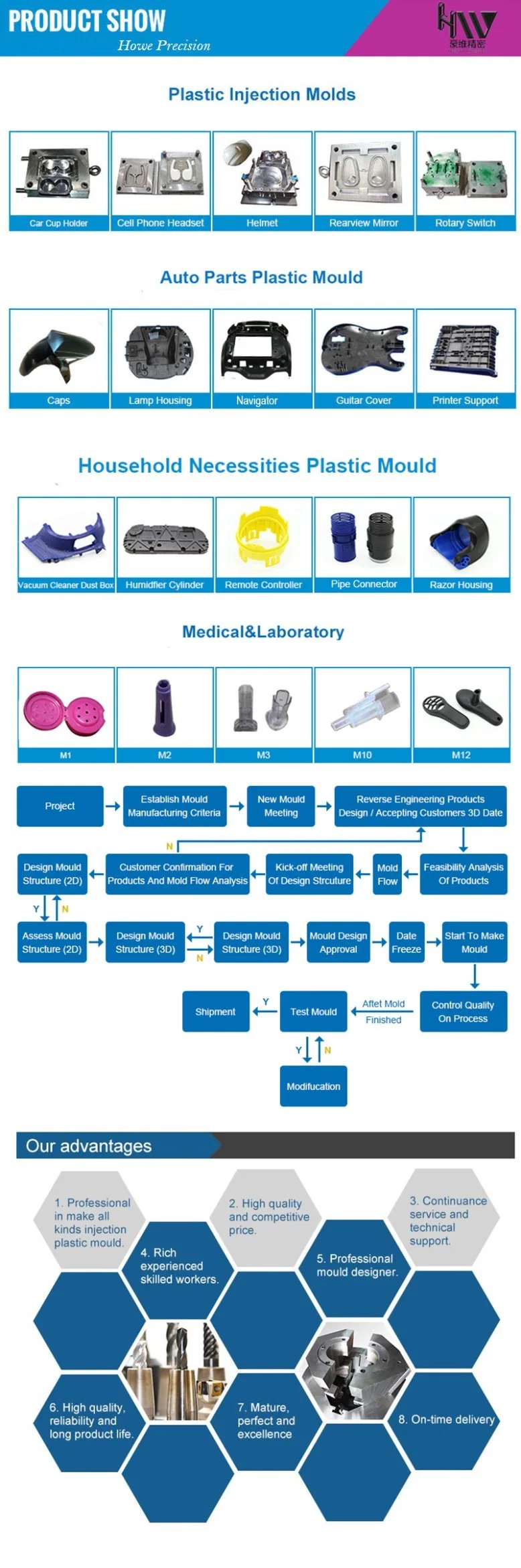

Process of mold making

Company profile

Our Services

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards. Our team of CAD designers will ensure that your imagination is incorporated into the actual product! If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!

Our products include :

1.Custom Plastic Injection Parts

2.Multi-cavity plastic parts

3.High Precision Molds

4.Insert & over molding

5.Double Shot Mold(2K mold)

6.Unscrewing Molding

7.Gas-assisted Molding

8.Die Casting Molding

9.Prototype plastic parts and Low cycle plastic parts molding

10Gas Assist molding

11.Elastomeric molding

12.IML & IMD part production

13.Thin wall plastic molding

14.High temperature molding

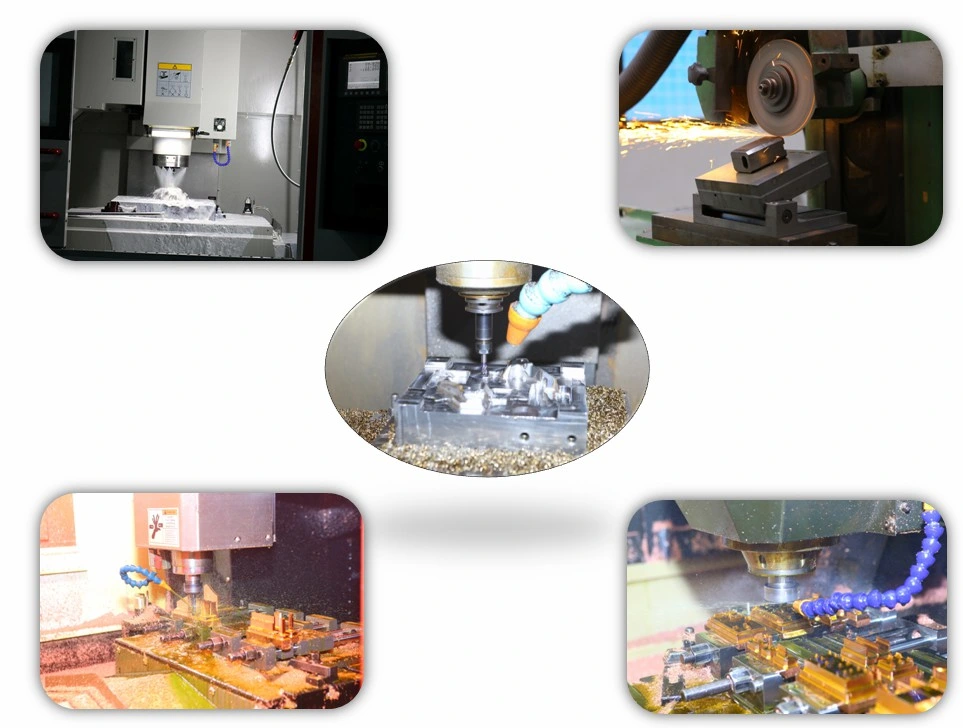

Our workshop

FAQ :

Q1: What kind of molds do you make?

A1: We are mainly making plastic mold injection and Die casting mold.

Sometimes we also make rubber molds according to our customer's requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept the following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customers or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, We can provide a steel certificate or hardness certificate to prove.

Q5: Can you make the texture/text/heat_treatment /nitriding for the injection mold plastic?

A5: Yes, As a plastic mold factory, we have long term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q6: How long is the lead-time for a plastic injection mold?

A6: It all depends on the mold's size and complexity. Normally, the lead time is 25-45 days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q7: Do you make spare parts for your customer?

A7: Yes, we will provide spare parts for the mold if needed or required by clients.

| Mould information | |

| Injection mold standard | HASCO,DME,MISUMI,China lKM Standard. |

| Please provide | 2D, 3D, samples, or the size of the multi-angle pictures. |

| Mould material | 45#, 50#, P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136 etc. |

| Product material | ABS,PA6,PA66,PP,PC,TPU,POM,PBT,PVC,TPE,TPV,TPO,TPR,EVA,LDPE etc. |

| Cavity | Single-cavity, Multi-cavity, or by request. |

| Runner system | Cold runner or Hot runner. |

| Mould precision | ±0.01mm. |

| Mould Life | 50-100 million shots. |

| Software | CAD, PRO-E, UG, etc. |

| Design Time | 1-3 days (normal circumstances). |

| Main technology | Milling, grinding, CNC, EDM, wire cutting, carving, lathes, etc. |

Process of mold making

| 1. Sample/Drawing | We need your detail requires clearly. |

| 2. Engineer Review | Material, cavity, Mould weight, give customer suggestion: |

| 3. Make quotation | Sales department and RD department make a meeting according to customer need |

| 4. Negotiation | Material, cavity, price, delivery time, payment term, etc. |

| 5. Place order | According to your own design or choosing our design. |

| 6. Mould design | We will communicate Exchange the opinion with you during making the drawing |

| 7. Tooling mould | After customers approve the mould design will start making mould. |

| 8. Mould process | Provide photos for customer show them tooling process |

| 9. Sample confirm | Send your sample to confirm it, if not satisfied by the customer. we modify mould. |

| 10. Delivery mould | Delivery mould after customer approve sample and arrange shipment. |

Company profile

Our Services

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards. Our team of CAD designers will ensure that your imagination is incorporated into the actual product! If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!

Our products include :

1.Custom Plastic Injection Parts

2.Multi-cavity plastic parts

3.High Precision Molds

4.Insert & over molding

5.Double Shot Mold(2K mold)

6.Unscrewing Molding

7.Gas-assisted Molding

8.Die Casting Molding

9.Prototype plastic parts and Low cycle plastic parts molding

10Gas Assist molding

11.Elastomeric molding

12.IML & IMD part production

13.Thin wall plastic molding

14.High temperature molding

Our workshop

FAQ :

Q1: What kind of molds do you make?

A1: We are mainly making plastic mold injection and Die casting mold.

Sometimes we also make rubber molds according to our customer's requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept the following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customers or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, We can provide a steel certificate or hardness certificate to prove.

Q5: Can you make the texture/text/heat_treatment /nitriding for the injection mold plastic?

A5: Yes, As a plastic mold factory, we have long term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q6: How long is the lead-time for a plastic injection mold?

A6: It all depends on the mold's size and complexity. Normally, the lead time is 25-45 days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q7: Do you make spare parts for your customer?

A7: Yes, we will provide spare parts for the mold if needed or required by clients.